The complete digital package for asphalt construction and earthworks

Automated compaction, real-time data, networked machines and enhanced safety

In 2026, roller manufacturer Hamm is offering an extensive assortment of innovative digital solutions to simplify and automate compaction in road construction and earthworks, opening up a new dimension of efficiency, quality and process reliability. At the heart of this assortment are the products Smart Compact Pro, Smart Compact for earthworks, Track Assist and WPT Compacting. The latest developments also elevate construction site safety to the next level.

Smart Compact Pro: Automated compaction based on real-time density

With Smart Compact Pro, Hamm becomes the first manufacturer in the world to integrate real-time density into the automated compaction process. The new technology will significantly increase the quality of asphalt compaction and the service life of roads, while simultaneously lowering the costs of road construction and renovation. Smart Compact Pro also ensures that compaction targets are achieved with precision, reducing the likelihood of additional expenditure as well as reducing the work involved in removing drill cores. With the help of the new Realtime Density Scan sensor, the density is still precisely calculated in real time, even for static compaction. Until now, real-time density was the missing piece of the asphalt compaction puzzle, which has now been found by Hamm in the form of Smart Compact Pro. Another benefit: The system is quick and easy to calibrate using a conventional measuring probe. The very first deployment of the system on a construction site was met with positive feedback, with Josef Hebel GmbH from Memmingen putting the Smart Compact Pro to the test by paving 21,000 m² of asphalt surface course. ‘This is a really important talking point for us when it comes to increasing quality in road construction and improving the longevity of the roads,’ explains senior site engineer Heinrich Lang. ‘The driver was delighted with the level of support the system offered him on the construction project. From an engineering perspective, we were also really impressed, because we received the density data from the construction site straight away in real time. These real-time densities are critical, because they allow us to react to any faults straight away and, in turn, ensure longer-lasting roads.’ With WPT Compacting, operators also have a tool to document real-time density data for an in-depth analysis of all performance and machine data.

Automatic compaction to a target value in earthworks

Another new addition is the HC 130i C VA compactors. These expand the existing product family of compactors with a VA drum (HC 200i C VA and HC 250i C VA) and also feature Smart Compact. By virtue of an infinitely variable amplitude and a newly developed compaction measurement system, this technology allows compactors to achieve automated compaction to a set target value in MN/m². As such, the new models offer not only reliable and homogeneous compaction, but also help to make building projects more cost-effective by reducing the number of double passes and lowering diesel consumption. The direct adjustment of the amplitude also effectively prevents jump operation and over-compaction, at the same time as protecting the machine and its operator from mechanical loads. What’s more, it makes the VA drum an energy-efficient system overall.

Track Assist: The digital assistant for roller drivers

The new Track Assist app for Android is the next phase in the development of the Smart Doc app and offers drivers an improved driving experience for asphalt construction and earthworks. It provides information on important compaction parameters, such as double passes, real-time density, temperature limits, changes in compaction value, reversing points or the proportion of jump operation. In the next stage of development, Track Assist will become a fully fledged assistance system that allows operators to compare compaction targets with up-to-date actual results.

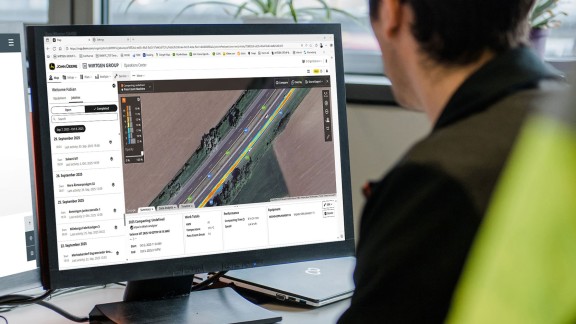

WPT Compacting: Efficiency for site managers and foremen

In combination with Track Assist, Hamm presents the Wirtgen Group Performance Tracker Compacting. WPT Compacting facilitates monitoring, documentation and analysis as well as reporting both during and after compaction. The process data captured using WPT Compacting, which includes the new real-time density measurements with Smart Compact Pro, are transferred to the central construction site and fleet management tool from Wirtgen Group, the John Deere Operations Center™, for accurate analysis and visualisation in a variety of views. Another feature is machine communication both between rollers and between rollers and pavers. Track Assist and WPT Compacting will be available from spring 2026.

Integrating systems for collision prevention

In road construction and earthworks operations, safety is always the top priority, as work in these sectors often present risks for workers on site. Hamm is turning to digital solutions in this regard too, to increase safety on construction sites and minimise the risk of accidents. For instance, all machines with the Easy Drive operating concept on the HC, HD+, HX and HP series feature an interface for integrating systems for collision prevention, either ex works or as a Retrofit solution. These technologies detect people or machines in the vicinity and warn the operator in time or, if necessary, take action via the machine control system to prevent collisions, for example by means of automatic deceleration or braking the machine to a complete stop. Soon Hamm will also offer a complete system ex works to prevent collisions.

Public Relations

Reinhard-Wirtgen-Straße 2

53578 Windhagen

Germany

Compactor with smooth drum

| Weight | 19,105 kg |

| Drum width | 2,140 mm |

| Manufacturer | DEUTZ |

Compactor with smooth drum

| Weight | 19,155 kg |

| Drum width | 2,140 mm |

| Manufacturer | DEUTZ |

Compactor with padfoot drum

| Weight | 19,465 kg |

| Drum width | 2,140 mm |

| Manufacturer | DEUTZ |

Compactor with padfoot drum

| Weight | 19,515 kg |

| Drum width | 2,140 mm |

| Manufacturer | DEUTZ |

Compactor with smooth drum

| Weight | 23,920 kg |

| Drum width | 2,140 mm |

| Manufacturer | DEUTZ |

Compactor with padfoot drum

| Weight | 24,390 kg |

| Drum width | 2,140 mm |

| Manufacturer | DEUTZ |

Compactor with vibration crusher drum

| Weight | 24,695 kg |

| Drum width | 2,140 mm |

| Manufacturer | DEUTZ |

Compactor with highly wear-resistant smooth drum

| Weight | 23,690 kg |

| Drum width | 2,140 mm |

| Manufacturer | DEUTZ |

Compactor with smooth drum

| Weight | 16,885 kg |

| Drum width | 2,140 mm |

| Manufacturer | DEUTZ |

Compactor with padfoot drum

| Weight | 16,715 kg |

| Drum width | 2,140 mm |

| Manufacturer | DEUTZ |

Compactor with VA drum

| Weight | 13,315 kg |

| Drum width | 2,140 mm |

| Manufacturer | JOHN DEERE |

Compactor with VA drum

| Weight | 13,535 kg |

| Drum width | 2,140 mm |

| Manufacturer | JOHN DEERE |