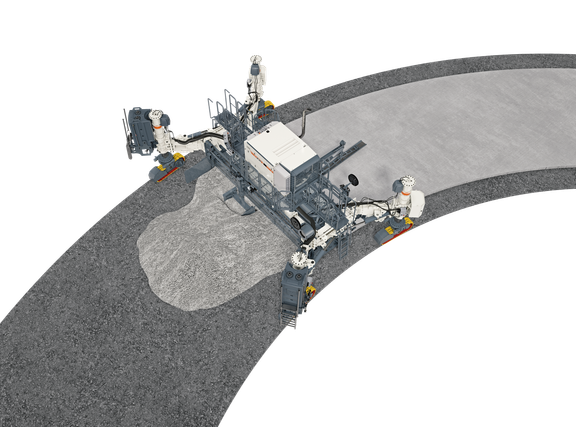

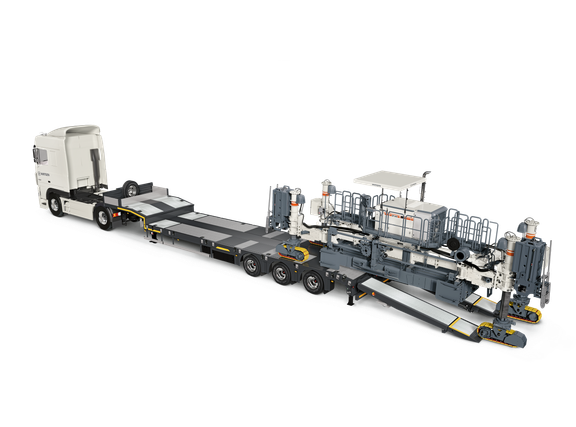

SP 64i Inset Slipform pavers

EU Stage 5/US EPA Tier 4f

6 ft 6 in - 24 ft

0 - 18 in

Fully Modular Inset Slipform Paver

Show less Highlights

Technical specifications

- Exhaust emissions category

- Number of crawler tracks

- Paving width

- Paving height

- Paving width with crown

- Paving width without crown

- Paving speed

- Machine weight

- Height adjustment, mechanical

- Rated power

-

- Exhaust emissions category

- EU Stage 5/US EPA Tier 4f

- Number of crawler tracks

- 4

- Paving width

- 6 ft 6 in - 24 ft

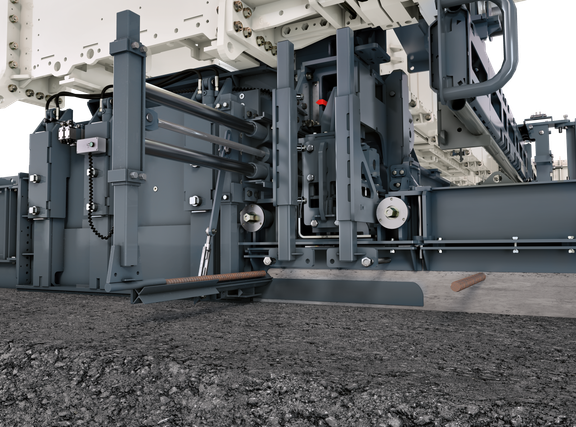

- Paving height

- 0 - 18 in

- Paving width with crown

- 12 ft - 24 ft

- Paving width without crown

- 6 ft 6 in - 24 ft

- Paving speed

- 0 - 6 m/min

- Machine weight

- 37,500 - 99,200 lbs

- Height adjustment, mechanical

- 17 in

- Rated power

- 180 kW / 241 hp

All details, illustrations and texts are non-binding and may include special equipment. We reserve the right to make technical changes without prior notice. Performance data are dependent upon actual operational conditions.