VF 500 Extending Screed

V

4 ft - 19 ft 6 in

8 ft

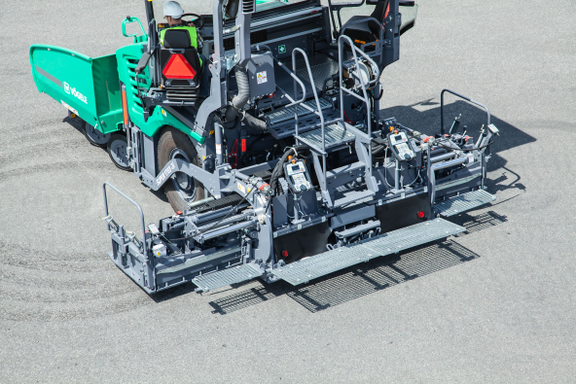

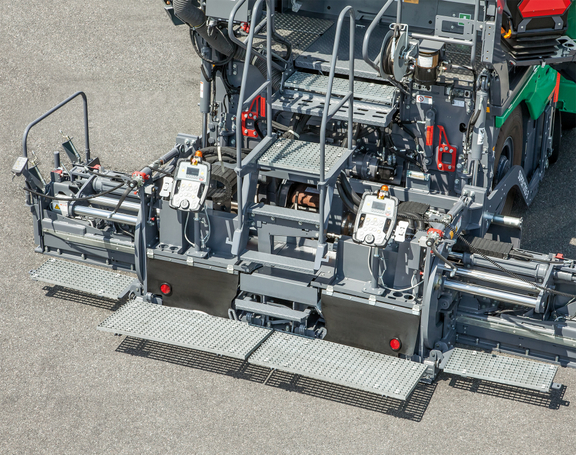

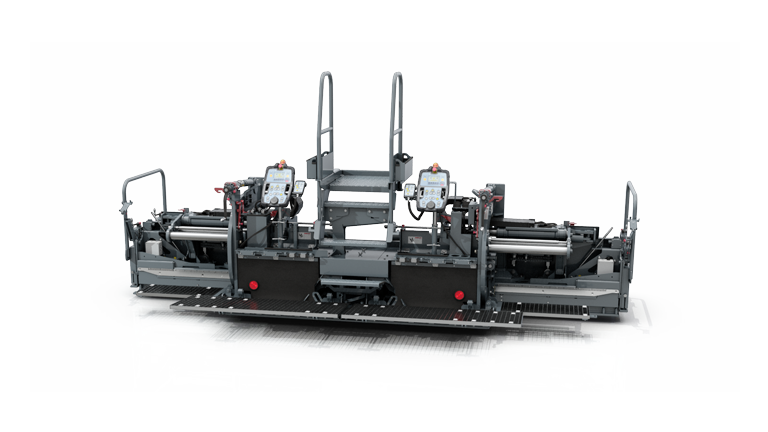

VÖGELE extending screed with front-mounted extensions

The VF 500 Extending Screed has been specially developed for the SUPER 1700-3i and SUPER 1703-3i pavers of the Universal Class. The VF 500 is ideal for applications which require a variable paving width, such as parking lots with islands and light masts, roads for residents only, urban roads with manhole covers, gas or water connections, junctions on highways or work on country roads, i.e. jobs which involve paving around obstacles.

Technical specifications

- Basic width

- Hydraulically adjustable

- Minimum paving width

- Maximum paving width

- Length

- Cut-off shoes

-

- Basic width

- 8 ft

- Hydraulically adjustable

- 8 ft to 15 ft 7 in

- Minimum paving width

- 4 ft

- Maximum paving width

- 19 ft 6 in

- Length

-

Bolt-on extensions 12 in 24 in

- Cut-off shoes

- 4 x 1 ft

- Version

- Crown adjustment

- Slope, extending units (max.)

- Berms

-

- Version

- hydraulic

- Crown adjustment

- -2 % to 5 %

- Slope, extending units (max.)

- 10 %

- Berms

- 12 in, 18 in, 24 in

- Compacting systems

- Vibrators (V)

- Version

- Frequency (max.)

-

- Compacting systems

- V

- Version

- eccentric vibrators

- Frequency (max.)

- 50 Hz

- Heating rods

- Output generation

- Control

-

- Heating rods

- on screed plates

- Output generation

- three-phase AC generator

- Control

- fully automatic, thermostat-controlled

- Width (without end gate)

- Weight of basic screed

- Depth (in transport position)

-

- Width (without end gate)

- 8 ft 6 in

- Weight of basic screed

-

Screed Weight V 6,500 lbs

- Depth (in transport position)

-

Screed Depth VF 500 4 ft

All details, illustrations and texts are non-binding and may include special equipment. We reserve the right to make technical changes without prior notice. Performance data are dependent upon actual operational conditions.