HD+ 90i PH VT-S Tandem roller with vibrating roller drum and set of wheels

8,960 kg

1,680 mm

EU Stage V / EPA Tier 4

Highlights

Show lessTechnical specifications

- Series

- Name

- Description

- Exhaust emissions category

- Series

-

- Series

- HD+

- Name

- HD+ 90i PH VT-S

- Description

- Tandem roller with vibrating roller drum and set of wheels

- Exhaust emissions category

- EU Stage V / EPA Tier 4

- Series

- H276

- Static linear load, front

- Operating weight with ROPS

- Operating weight with cab

-

- Static linear load, front

- 29.2 kg/cm

- Operating weight with ROPS

- 8,790 kg

- Operating weight with cab

- 8,960 kg

- Total length

- Total width with cab

- Maximum working width

- Total height with cab

- Centre distance

- Turning radius, inside

- Curb clearance, rear

- Curb clearance, left

-

- Total length

- 4,800 mm

- Total width with cab

- 1,800 mm

- Maximum working width

- 1,820 mm

- Total height with cab

- 3,010 mm

- Centre distance

- 3,600 mm

- Turning radius, inside

- 5,900 mm

- Curb clearance, rear

- 800 mm

- Curb clearance, left

- 800 mm

- Drum diameter, front

- Drum width, front

- Drum type, front

- Drum thickness, front

- Track offset, left

-

- Drum diameter, front

- 1,200 mm

- Drum width, front

- 1,680 mm

- Drum type, front

- Smooth/split

- Drum thickness, front

- 17 mm

- Track offset, left

- 170 mm

- Number of tyres, rear

- Tyre size, rear

- Width over tyres, rear

-

- Number of tyres, rear

- 4

- Tyre size, rear

- 11.00-20

- Width over tyres, rear

- 1,620 mm

- Manufacturer

- Model

- Cylinders, quantity

- Exhaust emission standard

- Exhaust gas after-treatment

- Power ISO 14396, rpm

- Power ISO 14396, HP

- Power ISO 14396, kW

- Power SAE J1349, rpm

- Power SAE J1349, HP

- Power SAE J1349, kW

-

- Manufacturer

- DEUTZ

- Model

- TCD 2.9 L4

- Cylinders, quantity

- 4

- Exhaust emission standard

- EU Stage V / EPA Tier 4

- Exhaust gas after-treatment

- DOC-DPF

- Power ISO 14396, rpm

- 2,300 rpm

- Power ISO 14396, HP

- 75.3 HP

- Power ISO 14396, kW

- 55.4 kW

- Power SAE J1349, rpm

- 2,300 rpm

- Power SAE J1349, HP

- 74.2 hp

- Power SAE J1349, kW

- 55.4 kW

- Regulation, infinitely variable

- Speed, transport gear

- Climbing ability, with vibration

- Speed, working gear, I

-

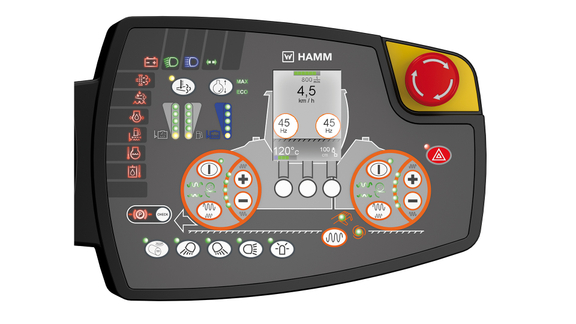

- Regulation, infinitely variable

- HAMMTRONIC

- Speed, transport gear

- 0-12,0

- Climbing ability, with vibration

- -

- Speed, working gear, I

- 0-6,0

- Centrifugal force, front, II

- Centrifugal force, front, I

- Amplitude, front, II

- Amplitude, front, I

- Vibration frequency, front, II

- Vibration frequency, front, I

-

- Centrifugal force, front, II

- 78 kN

- Centrifugal force, front, I

- 84 kN

- Amplitude, front, II

- 0.4 mm

- Amplitude, front, I

- 0.61 mm

- Vibration frequency, front, II

- 50 Hz

- Vibration frequency, front, I

- 42 Hz

- Steering, type

- Oscillation angle +/-

-

- Steering, type

- Articulated steering

- Oscillation angle +/-

- 10 °

- Water sprinkling, type

-

- Water sprinkling, type

- Pressure

- Fuel tank, capacity

- Water tank, capacity

- Additive tank, capacity

-

- Fuel tank, capacity

- 173 l

- Water tank, capacity

- 760 l

- Additive tank, capacity

- 22 l

- Acoustic power LW(A), measured

- Sound power level L(WA), guaranteed

-

- Acoustic power LW(A), measured

- 103 db(A)

- Sound power level L(WA), guaranteed

- 106

Downloads

Related products

HD+ 90i PH VV

Tandem roller with two vibrating roller drums

| Weight | 9,220 kg |

| Drum width | 1,680 mm |

| Exhaust emissions category | EU Stage V / EPA Tier 4 |

HD+ 90i PH VO-S

Tandem roller with vibration and oscillation drum

| Weight | 9,460 kg |

| Drum width | 1,680 mm |

| Exhaust emissions category | EU Stage V / EPA Tier 4 |

HD+ 90i PH VT

Tandem roller with vibrating roller drum and set of wheels

| Weight | 8,720 kg |

| Drum width | 1,680 mm |

| Exhaust emissions category | EU Stage V / EPA Tier 4 |

HD+ 90i PH VO

Tandem roller with vibration and oscillation drum

| Weight | 9,220 kg |

| Drum width | 1,680 mm |

| Exhaust emissions category | EU Stage V / EPA Tier 4 |

HD+ 90i PH VV-S

Tandem roller with two vibrating roller drums

| Weight | 9,700 kg |

| Drum width | 1,680 mm |

| Exhaust emissions category | EU Stage V / EPA Tier 4 |

All details, illustrations and texts are non-binding and may include special equipment. We reserve the right to make technical changes without prior notice. Performance data are dependent upon actual operational conditions.