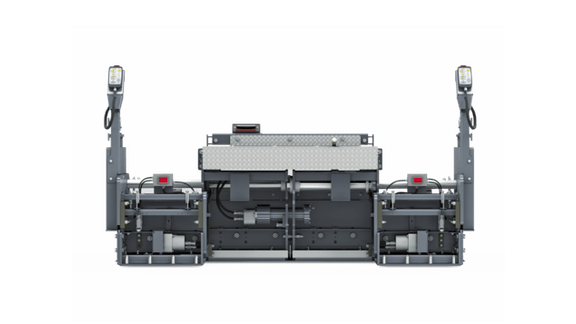

Mini Class SUPER 700i paver

From the East Coast to the far West, contractors are learning that the versatile SUPER 700i gives them the means to tackle paving projects from bike paths, to shoulders, to utility cuts, to parking lots, and even residential streets and country roads. The SUPER 700i is a small-sized asphalt paver that provides big productivity and profitability, as demonstrated by two jobs in Ogden, Utah and Bethesda, Maryland.

Ogden | Utah

In Utah, a SUPER 700i demonstrated its utility and ease of use when it paved both a bike path and a utility cut in the same morning. In Ogden, forces of Aspen Paving Inc. used their new SUPER 700i to place a 6-ft.-wide bike path 6 in. deep in a subdivision under construction, then trailered it to south Ogden where it paved a 6-ft.-wide secondary water line cut much faster, and with more precision and smoothness, than the toss-and-roll method the firm previously used.

For the path, a 0.5-in. NMAS hot asphalt mix containing 15% RAP was placed on a graded berm. The 480-ft. long patch for Pineview Water Systems filled a cut which had been backfilled by Pineview following a water line replacement. “The SUPER 700i will go down narrow enough to go in the cut with its tracks,” said Bart LaRose, vice president at Aspen. “We bought this machine primarily for paving 8 ft. wide and down.” If paving a trench less than 3 ft. wide, the paver’s tracks will straddle the trench with the screed lowered. “Anything bigger than 3 ft. is perfect, and anything smaller than 3 ft. is perfect,” said Mike LaRose, president of Aspen. “Exactly 3 ft. is tough because you have one track in the trench and one out. That’s where the versatility of this paver comes in. We can do a lot of small stuff, but also go up to a 7-ft.-wide trench.”

Acquired in spring 2017, the SUPER 700i relieves Aspen of having its teams do extensive work by hand. “We use it on our smaller jobs, as it saves us hand work and gives us a smoother product,” he said. “It speeds our jobs up quite a bit and improves the quality.” After acquiring the paver in early 2017, Aspen had been leveling its placements by hand. Later the Niveltronic Basic Automated System for Grade and Slope Control was installed to better refine placements. Fully integrated into ErgoBasic control system, Niveltronic Basic is easy to use, with a separate remote control unit for each side of the screed.

“We did our leveling manually, but with the automated system we now don’t have to have two guys on the machine, freeing one up for other work. Once it’s set up, the operator can run the whole machine, so we don’t have to have two screed men, or even one. Now the workers can do other things on the job,” Bart LaRose said. “Anything you do with a paver, versus by hand, will give you a better end result,” Mike LaRose said. “That’s why we purchased this machine. The Niveltronic Basic system is easier on the guys because they can’t crank the screed fast enough, while the automatic system does it for them. Our end result is smoother and our quality is better.”

For the Pineview utility cut, a 0.75-in. NMAS standard hot asphalt mix containing 5% liquid asphalt and 30% RAP was being placed by the VÖGELE paver 6 in. deep in two 3-in. lifts, for a total of 110 tons. “That’s where this little paver comes in handy,” said Mike LaRose. “Because of the grade of the backfill, if we were doing it by hand, the patch surface would stay rough. But the paver will take the roughness out, because the screed blows through the inconsistencies in the grade. The paver’s quality makes our final product better, and gets it placed faster. It’s a great deal for us.” The larger aggregate used in the utility patch – compared to the trail path – is used to stand up better to vehicular traffic that would not be present on the path. “On the utility patch we are shooting for 95 to 96% density,” Mike LaRose said. “That’s where this little paver helps too; when you place patches with skid steer loaders or hand shovels, you’re not getting any initial compaction. But when it’s coming out of that vibratory screed, it’s getting compaction early on.”

The SUPER 700i’s maneuverability makes transport easier, said Bart LaRose. “You can get in and out of anything,” he said. And its asymmetrical material hopper – in which one hopper wing can raise or lower independently of the other – allows this mini-paver to be easily fed with material in extremely confined spaces. “When we have to go by a mailbox or a wall, we can bring a wing up and pave right next to it,” Bart LaRose said. “The hopper wings fold up nicely so you can get into tighter areas. If trucks can’t get in, you can get a dump in it, fold it up, and be on your way. We have the option of placing shoulders with the paver, although we haven’t done that yet. We’re still learning about its capabilities. It’s performed really well and done everything that they said it would do.”

Aspen purchased the paver sight-unseen from Honnen Equipment in Salt Lake City. “My salesman, Marc Robinson, brought me a brochure,” Mike LaRose said. “We didn’t even look at the paver. Marc knew our scope of work, and knew the SUPER 700i would be right for us. Based on what I’ve experienced I would not buy any other small paver out on the market.”

Mike LaRose, President Aspen Paving Inc.

Bethesda | Maryland

On the other side of the country, a utility contractor uses its new WIRTGEN cold milling machine and SUPER 700i paver to finish underground pipe work in Maryland. There, in summer 2017, Rivers Construction Group Ltd., Jessup, Md., was using its new 5-ft. Wirtgen W 120 CFi cold milling machine to remove a temporary utility patch in advance of final patch placement by the SUPER 700i within a residential neighborhood in Bethesda. Rivers was founded in 2006 by the current President Luis Rivera, his brother Romero (now Vice President), and employed a single helper. Eleven years later it has gone from three employees to 135, and specializes in underground utility construction including water mains, water meter vaults, sewers, storm drainage, and concrete flatwork like sidewalks, aprons, curbs, gutters and driveways.

“We concentrate on sewer and water utility construction, roadways and concrete,” Rivera said. “In many cases now, instead of removing pavement with an excavator, we bring our cold milling machine in to dig the asphalt out, and then follow with the backhoe to remove fill.” Thus the combo of the WIRTGEN “Compact” W 120 CFi and SUPER 700i leverages time and enhances profitability for Rivers Construction, in addition to providing a better end product. “These machines save time and make money for us,” Rivera said. “We can do the work faster, and we work to our own schedules, rather than a subcontractor’s. They allow us to do three times as much work as before.”

And there is a tangential benefit to Rivers Construction upgrading its equipment with the WIRTGEN milling machine and VÖGELE paver. “It also creates respect for us when our customers see the milling machine and paver on the job site. It’s completely different from laying asphalt with excavator or shovels. When they see our new equipment their faces change immediately. For us, it’s a big, big change and a great benefit.” When cutting pavement for a utility repair, Rivers will cut 10 in. deep, although the W 120 CFi can go a full 13 in. deep. “All we do is reveal the fill surrounding the pipes, and a backhoe finishes the job in advance of the hand work around the pipe,” Rivera said.

Luis Rivera, President Rivers Construction Group, Ltd.

For placement of the 19.5-mm NMAS asphalt hot mix, Rivers Construction likes to situate its SUPER 700i with both tracks in the trench. If there’s enough room in the road, the paver will be fed by truck; otherwise, as in the case of Bethesda, the paver is fed by skid steer loader. The mix is compacted to at least 95% density with help from the AB 220 V Extending Screed with vibration.

Typically, if the trench is 8 in. deep, 6 in. of asphalt will be placed in the trench by loader, compacted, and then followed by the final 2-in. driving surface placed by the SUPER 700i. “We can’t keep up without the paver,” Rivera said. “We will pave about 1,000 linear feet of water main today. There is no way we can do it with excavator and by hand, unless we double or triple the number of people, and we still won’t have the quality driving surface we want. With the SUPER 700i, we’ve gone from an average 150 to 750 linear feet per day. Everything is better.”

Large material hopper: With a capacity of 5.8 t, the receiving hopper is designed to ensure a steady supply of mix without bottlenecks.

Rivers counts on its distributor, Elliott & Frantz, Inc., to keep its WIRTGEN GROUP equipment working. “They make sure our equipment, both cold milling machine and paver, are available whenever we need them.” A win-win situation: “Rivers Construction benefits from the higher quality of the patch from the paver, as well as the higher productivity,” said Bob Schaeffer, President, Elliott & Frantz, Inc., equipment distributor for Rivera.

Its small footprint and low profile, with a minimum clearance of 4 ft. 7 in. – combined with its easy maneuverability – makes it suitable for paving interior facilities with their tight spaces, as well as driveways and roadways outdoors. For high productivity, the SUPER 700i can pave up to 98 fpm with a laydown rate up to 280 tph. And to make things easier, it comes equipped with VÖGELE’s ErgoBasic operating system which provides intuitive paver control that’s as good as those found on the big machines.

ErgoBasicTracked paver Mini Class

| Basic width | 4 ft 4 in |

| Paving width, max. | 10 ft 6 in |

| Maximum laydown rate | 275 US t/hr |

Extending screed

| Compacting systems | V, TV |

| Paving width of the screed | 1 ft 8 in - 11 ft 6 in |

| Basic width | 3 ft 11 in |