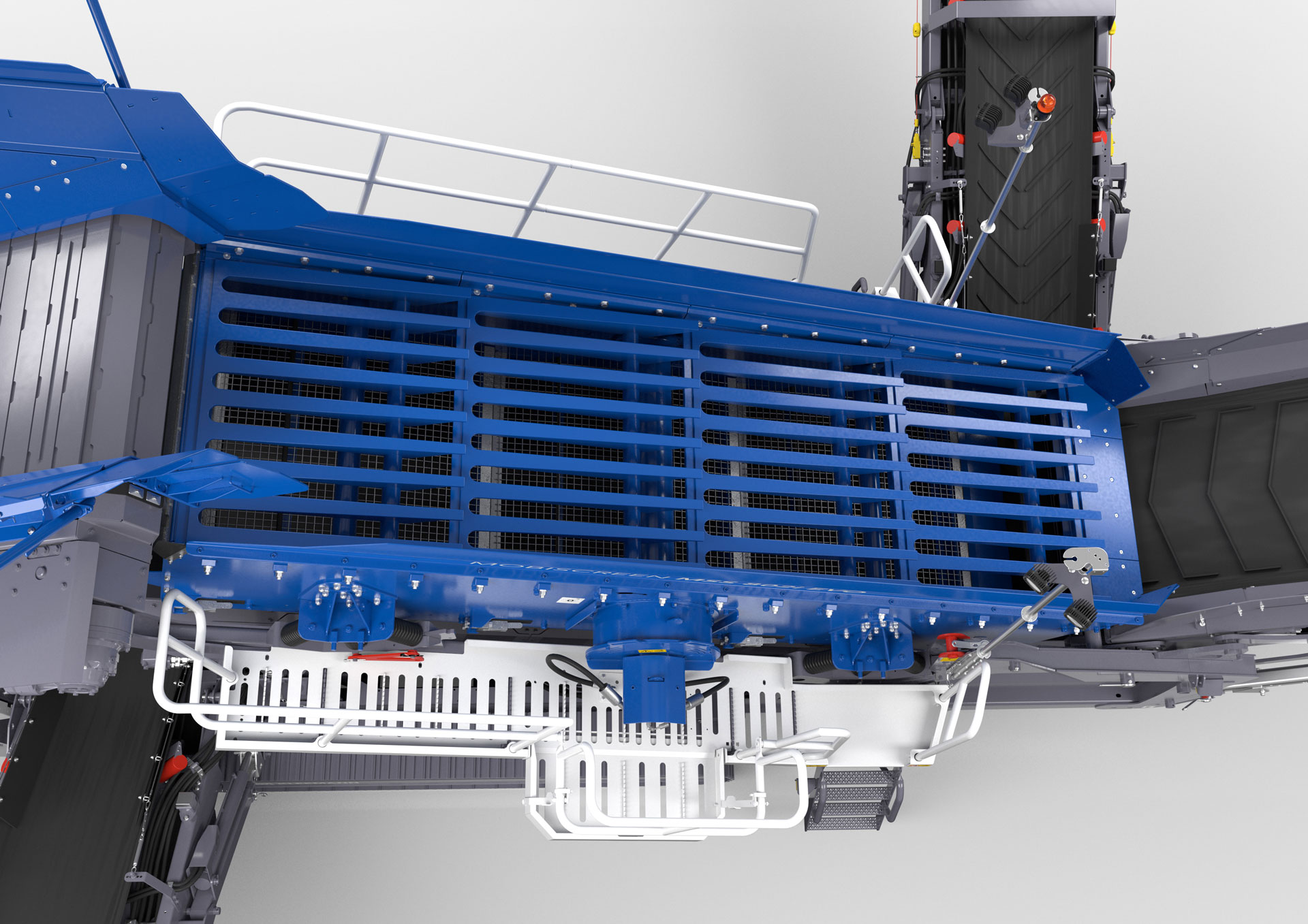

MSS 1102 PRO Mobile coarse screening plant

US t/hr

Properties

The MOBISCREEN MSS 1102 PRO mobile screening plant is mainly used as a coarse screen in quarries and large earthmoving projects. The extensive range of screening media and the simple adjustment of the screening parameters make it easy to adapt the screening plant to new operating conditions. It is conveniently operated via a modern control system. Maintenance work can be carried out easily thanks to good accessibility. Translated with DeepL.com (free version)

Show lessFlexibility, operability and ergonomics: the powerful mobile scalping screens MOBISCREEN MSS 502 EVO, MSS 802 EVO and MSS 1102 PRO impress in different areas of application and differ primarily in their size.

Technical specifications

- Max. feed size

- Feed height

- Feed capacity up to approx.

- Hopper volume

-

- Max. feed size

- 35 in x 22 in x 13 in

- Feed height

- 12 ft 10 in

- Feed capacity up to approx.

- 827 US t/hr

- Hopper volume

- 16.1 yd³

- Width x length

- Length

-

- Width x length

- 56 in x 14 ft 9 in

- Length

- 14 ft 9 in

- Width x length

-

- Width x length

- 56 in x 7 ft 17 in

- Width approx.

- Length approx.

- Discharge height min. approx. [Imperial]

- Discharge height max. approx.

-

- Width approx.

- 40 in

- Length approx.

- 27 ft 1 in

- Discharge height min. approx. [Imperial]

- 10 ft x 1 in

- Discharge height max. approx.

- 13 ft x 7 in

- Width x length

- Discharge height max. approx.

-

- Width x length

- 40 in x 1 ft 27 in

- Discharge height max. approx.

- 13 ft

- Width x length

- Discharge height max. approx.

-

- Width x length

- 63 in x 24 ft 9 in

- Discharge height max. approx.

- 16 ft 2 in

- Drive concept

- Rated speed

- Power pack manufacturer

- Power supply unit output

-

- Drive concept

- H-DRIVE (Diesel-hydraulic)

- Rated speed

- 1,800 rpm

- Power pack manufacturer

- John Deere

- Power supply unit output

- 220 hp

- Transport height approx. (standard value)

- Transport length approx.

- Transport width approx.

- Transport weight of basic plant

- Transport weight max. configuration approx.

-

- Transport height approx. (standard value)

- 11 ft 9 in

- Transport length approx.

- 59 ft 11 in

- Transport width approx.

- 9 ft 10 in

- Transport weight of basic plant

- 86,250 lbs

- Transport weight max. configuration approx.

- 103,650 lbs

- Type

- Upper deck (W x L)

- Lower deck (W x L)

- Upper deck width

- Lower deck width

-

- Type

- Double deck screen for coarse elements

- Upper deck (W x L)

- 6 ft x 0 in x 20 ft x 0 in

- Lower deck (W x L)

- 6 ft x 0 in x 17 ft x 7 in

- Upper deck width

- 6 ft x 0 in

- Lower deck width

- 6 ft x 0 in

All details, illustrations and texts are non-binding and may include special equipment. We reserve the right to make technical changes without prior notice. Performance data are dependent upon actual operational conditions.