Wirtgen | AutoTrac for the WR Series

Presentation of the New Automation Technology for Cold Recyclers and Soil Stabilizers at Bauma 2022

In view of growing demands for environmentally compatible processes, the need for responsible handling of valuable resources is also increasing in the areas of soil stabilization and cold recycling. Cost-effective realization of these processes is only possible when they are efficiently executed. With the launch of the AutoTrac system for the WR series, Wirtgen now offers a technology that focuses precisely on this.

Groundbreaking Technology for Soil Stabilization and Cold Recycling

Soil stabilizers are used, for example, for resource-efficient preparation of road beds in the course of infrastructure projects. A sub-base with insufficient load bearing capacity is transformed into resilient ground that can withstand heavier loads. This process takes the existing soil material and simply adds and mixes in binding agents such as cement and/or lime. In the case of cold recycling with WR series machines, damaged asphalt layers are milled and resized in a single operation, re-bound by the addition of binding agents and water and then repaved. New base layers produced in-place by this process are characterized by their extremely high load bearing capacity.

The new Wirtgen AutoTrac system for the WR series impresses with its essential contribution to the conservation of resources and increased efficiency.

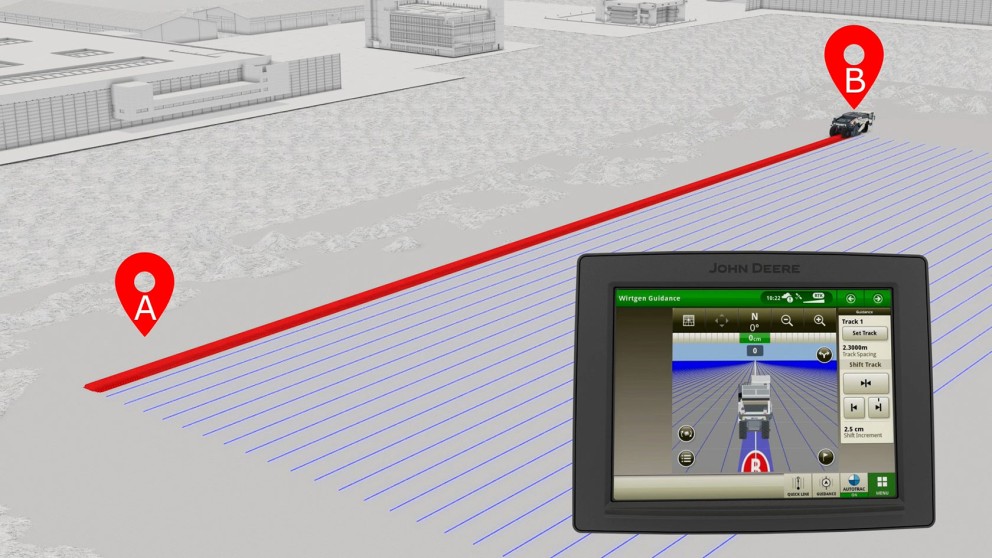

Automatic Steering System for Optimal Overlaps

By enabling precise, automatic steering, the AutoTrac system helps Wirtgen wheeled recyclers to achieve greater process efficiency and, as a result of this, a high degree of environmental compatibility. It steers the machine accurately within tolerances of a few centimeters on the basis of a previously calculated reference strip and a specified overlap of adjacent strips, which enables consistent utilization of the machine’s ideal working width. AutoTrac relies, among other things, on various global navigation satellite systems (GNSS) for precise determination of the machine’s position and direction of travel. The system is operated from an additional control panel that also enables the operator to view information about the position of the machine and previously completed strips.

Leverage Savings Potentials and Increase Process Quality

If one considers the sum of the large, avoidable overlaps with neighboring strips that can occur in manual operations, and the corresponding wastage of resources, the potential savings the system can bring soon become clear. Adhering to the preset overlaps reduces the consumption of binding agents, consumables, and fuel, makes the carbon footprint smaller, and shortens the project completion time. The consequence of this is increased process efficiency, which simultaneously cost-effectiveness and environmental compatibility. Manual steering of the machine always requires considerable effort when it comes to avoiding unprocessed gaps in the ground being worked. Here too, the automatic steering system assists the operator and reduces the workload. Maintaining the desired overlap avoids unwanted gaps in the final results. The operator can then concentrate entirely on the mixing process and keeping an eye on what’s going on around the machine.

The AutoTrac automatic steering system makes Wirtgen cold recyclers and soil stabilizers even more efficient.

Public Relations

Reinhard-Wirtgen-Straße 2

53578 Windhagen

Germany