MC 120 PRO Mobile jaw crusher

E-DRIVE (Diesel-electric)

1,080 mm x 680 mm x 410 mm

650

t/h

Properties

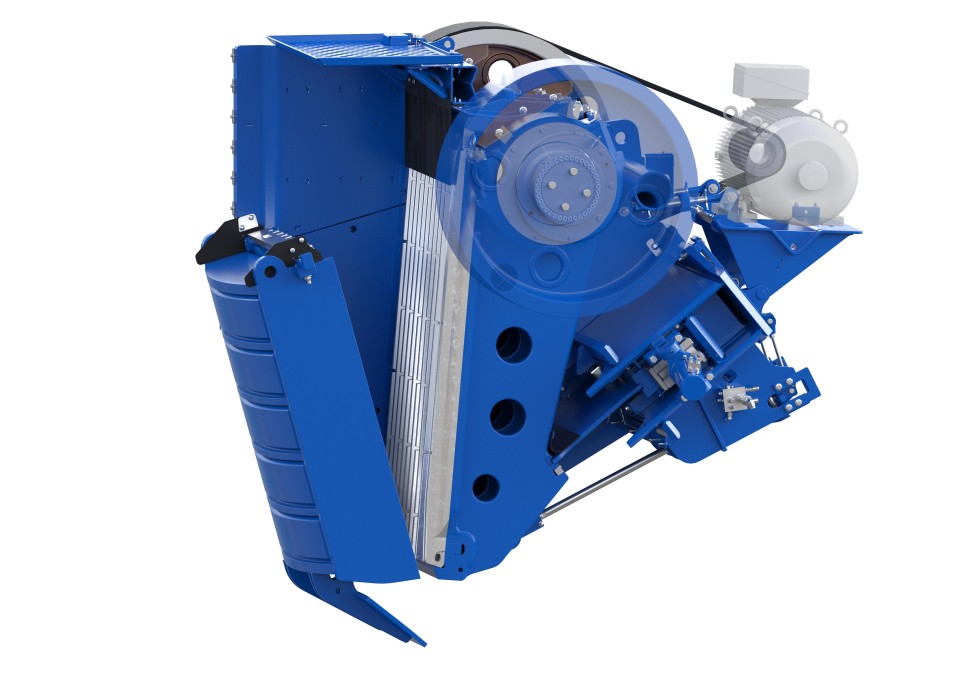

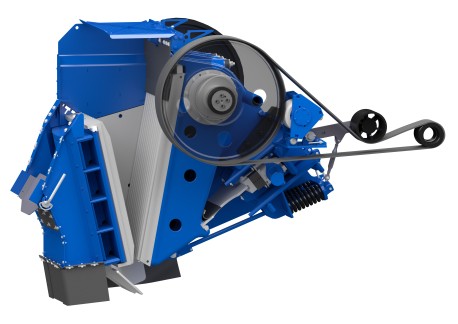

The MOBICAT MC 120 PRO, the first jaw crusher in the PRO line, is used for pre-crushing almost all types of natural stone. The jaw crusher is extremely robust and impresses with its low-maintenance operation. The machine therefore guarantees high production outputs.

Show less Highlights

The jaw crusher MOBICAT MC 120 PRO is extremely robust and impresses with its low-maintenance operation. The machine also guarantees high production outputs.

Technical specifications

- Max. feed size

- Feeding height

- Feed height with extension

- Feed capacity up to approx.

- Hopper width

- Hopper width with extension

- Hopper length

- Hopper length with extension

- Hopper volume

- Hopper volume with extension

-

- Max. feed size

- 1,080 mm x 680 mm x 410 mm

- Feeding height

- 4,930 mm

- Feed height with extension

- 5,280 mm

- Feed capacity up to approx.

- 650 t/h

- Hopper width

- 2,850 mm

- Hopper width with extension

- 3,900 mm

- Hopper length

- 4,100 mm

- Hopper length with extension

- 3,910 mm

- Hopper volume

- 9.7 m³

- Hopper volume with extension

- 13 m³

- Width x length

-

- Width x length

- 1,110 mm x 3,600 mm

- Width x length

- Model

-

- Width x length

- 1,200 mm x 2,900 mm

- Model

- Double-deck heavy-piece screen

- Discharge height

- Width

- Length

-

- Discharge height

- 3,450 mm

- Width

- 650 mm

- Length

- 6,650 mm

- Crusher drive type

- Crusher inlet (W x D)

- Crusher weight (approx.)

- Crushing power

- Single toggle jaw crusher model

- Gap setting

- Adjustment range of gap width

-

- Crusher drive type

- Electric

- Crusher inlet (W x D)

- 1,200 mm x 800 mm

- Crusher weight (approx.)

- 29,200 kg

- Crushing power

- 200 kW

- Single toggle jaw crusher model

- STR120

- Gap setting

- Fully hydraulic

- Adjustment range of gap width

- 70 mm - 200 mm

- Crushing capacity CSS = 100 mm up to approx.

- Crushing capacity CSS = 130 mm up to approx.

- Crushing capacity CSS = 160 mm up to approx.

-

- Crushing capacity CSS = 100 mm up to approx.

- 250 t/h

- Crushing capacity CSS = 130 mm up to approx.

- 325 t/h

- Crushing capacity CSS = 160 mm up to approx.

- 400 t/h

- Discharge height approx.

- Discharge height, extended approx.

- Width

- Length

- Length, extended

-

- Discharge height approx.

- 4,000 mm

- Discharge height, extended approx.

- 4,550 mm

- Width

- 1,200 mm

- Length

- 12,300 mm

- Length, extended

- 13,900 mm

- Width x length

-

- Width x length

- 1,300 mm x 2,000 mm

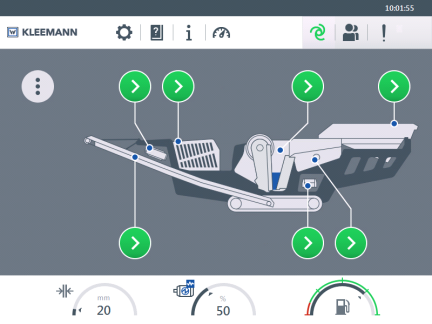

- Drive concept

- Generator

- Power pack manufacturer

- Power supply unit output

- Rated speed

-

- Drive concept

- E-DRIVE (Diesel-electric)

- Generator

- 500 kVA

- Power pack manufacturer

- Scania

- Power supply unit output

- 371 kW - 410 kW

- Rated speed

- 1,800 U/min

- Transport height approx. (default value)

- Transport length approx.

- Transport width approx.

- Transport weight of basic plant approx.

- Transport weight max. configuration approx.

-

- Transport height approx. (default value)

- 4,100 mm

- Transport length approx.

- 19,355 mm

- Transport width approx.

- 3,000 mm

- Transport weight of basic plant approx.

- 72,500 kg

- Transport weight max. configuration approx.

- 86,500 kg

All details, illustrations and texts are non-binding and may include special equipment. We reserve the right to make technical changes without prior notice. Performance data are dependent upon actual operational conditions.

_PRO_Highlight_film.jpg)