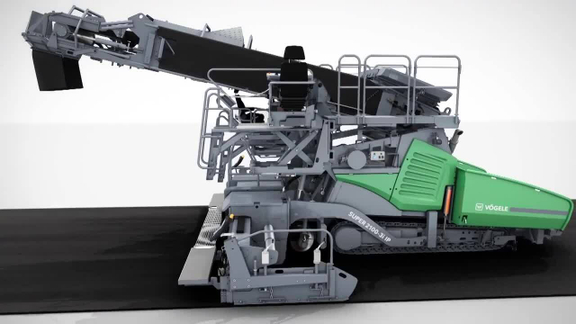

SUPER 2100-3i IP Tracked paver Special Class

m

m

t/h

The economical paving method for compact asphalt pavements

InLine Pave is the innovative process developed by VÖGELE for building compact asphalt pavements. The heart of the InLine Pave train is the SUPER 2100-3i IP for placing the binder course. It is a modified standard paver with a special transfer module for the surface course material and an AB 600 Extending Screed in the TP2 Plus version. With its special tamper, two pressure bars and extra weights, it achieves extremely high density values. Based on VÖGELE’s unique pulsed-flow hydraulics, this screed is the jewel in the crown of InLine Pave technology.

Show lessTechnical specifications

- Engine

- Version

- Manufacturer

- Type

- Exhaust emissions standard

- Exhaust emissions after-treatment

- Nominal output

- ECO mode output

- Emission data

- Guaranteed sound power level LWA

- Sound pressure level LPA at the operator’s stations (≤)

- Fuel tank

-

- Version

- liquid-cooled 6-cylinder diesel engine

- Manufacturer

- Cummins

- Type

- B6.7 - C250

- Exhaust emissions standard

- European exhaust emissions standard V, US standard EPA Tier 4f

- Exhaust emissions after-treatment

- DOC, DPF, SCR

- Nominal output

- 186 kW / 2,000 U/min

- ECO mode output

- 187 kW / 1,700 U/min

- Guaranteed sound power level LWA

- 108 db(A)

- Sound pressure level LPA at the operator’s stations (≤)

- 80 db(A)

- Fuel tank

- 380 l

- Undercarriage

- Version

- Ground contact

- Traction drive crawler tracks

- Lubrication of track rollers

- Track tension adjuster

- Speeds

- Pave speed (up to)

- Travel speed (up to)

-

- Version

- provided with rubber pads

- Ground contact

- 3,060 mm x 305 mm

- Traction drive crawler tracks

- separate hydraulic drives with electronic control

- Lubrication of track rollers

- lifetime

- Track tension adjuster

- spring assembly

- Pave speed (up to)

- 25 m/min

- Travel speed (up to)

- 4.5 km/h

- Hopper capacity

- Width

- Feed height (bottom of material hopper)

- Push-rollers

- Standard

- Positions

- Option

-

- Hopper capacity

- 14 t

- Width

- 3,265 mm

- Feed height (bottom of material hopper)

- 590 mm

- Standard

- oscillating

- Positions

- can be adjusted in a forward direction by 75 mm or 150 mm

- Option

- sprung (PaveDock)

- Conveyors

- Number

- Version

- Drive

- Speed (up to)

- Augers

- Number

- Version

- Diameter

- Drive

- Rpm (up to)

- Height

- Standard height

- Lubrication

-

- Number

- 2

- Version

- with replaceable feeder bars, direction of conveyor temporarily reversible

- Drive

- separate hydraulic drives, proportional control

- Speed (up to)

- 45 m/min

- Number

- 2

- Version

- with replaceable auger blades, auger rotation reversible

- Diameter

- 480 mm

- Drive

- separate hydraulic drives, proportional control

- Rpm (up to)

- 84 U/min

- Height

- infinitely variable

- Standard height

- hydraulically adjustable by 15 cm

- Lubrication

- centralized lubrication system, electrically-driven grease pump

- Belt width

- Conveyor

- Conveying system capacity

- Screed heating

- Track tension adjuster

-

- Belt width

- 1,100 mm

- Conveyor

- 1, with hydraulic drive

- Conveying system capacity

- 900 t/h

- Screed heating

- infrared heating panel, diesel-operated

- Track tension adjuster

- hydraulic

All details, illustrations and texts are non-binding and may include special equipment. We reserve the right to make technical changes without prior notice. Performance data are dependent upon actual operational conditions.