MR 130i EVO2 Mobile impact crusher

t/h

Properties

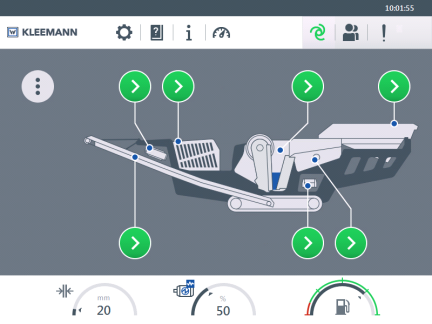

The mobile impact crusher MOBIREX MR 130i EVO2 can be deployed universally as an all-rounder and produces first-class final grain quality. With a crusher inlet width of 1300 mm, it achieves a production rate that until now was only associated with considerably larger crushing plants. This is made possible by outstanding cost effectiveness and performance with a variety of technical highlights. Thanks to its compact design, the plant is easy to transport and can be assembled and disassembled quickly.

Show lessVersatile application options, simple transport, short set-up times, high machine availability: The mobile impact crushers MOBIREX EVO2

Technical specifications

- Max. feed size

- Feed height

- Feed height with extension

- Feed capacity up to approx.

- Hopper width

- Hopper width with extension

- Hopper length

- Hopper length with extension

- Hopper volume

- Hopper volume with extension

-

- Max. feed size

- 1,040 mm x 650 mm x 390 mm

- Feed height

- 4,350 mm

- Feed height with extension

- 4,710 mm

- Feed capacity up to approx.

- 450 t/h

- Hopper width

- 2,250 mm

- Hopper width with extension

- 3,000 mm

- Hopper length

- 3,700 mm

- Hopper length with extension

- 3,700 mm

- Hopper volume

- 5 m³

- Hopper volume with extension

- 9 m³

- Width x length

-

- Width x length

- 1,000 mm x 2,614 mm

- Width x length

- Type

-

- Width x length

- 1,210 mm x 2,300 mm

- Type

- Double-deck heavy-piece screen

- Discharge height

- Discharge height, extended

- Width

- Length

- Length, extended

-

- Discharge height

- 2,900 mm

- Discharge height, extended

- 3,650 mm

- Width

- 650 mm

- Length

- 4,000 mm

- Length, extended

- 6,000 mm

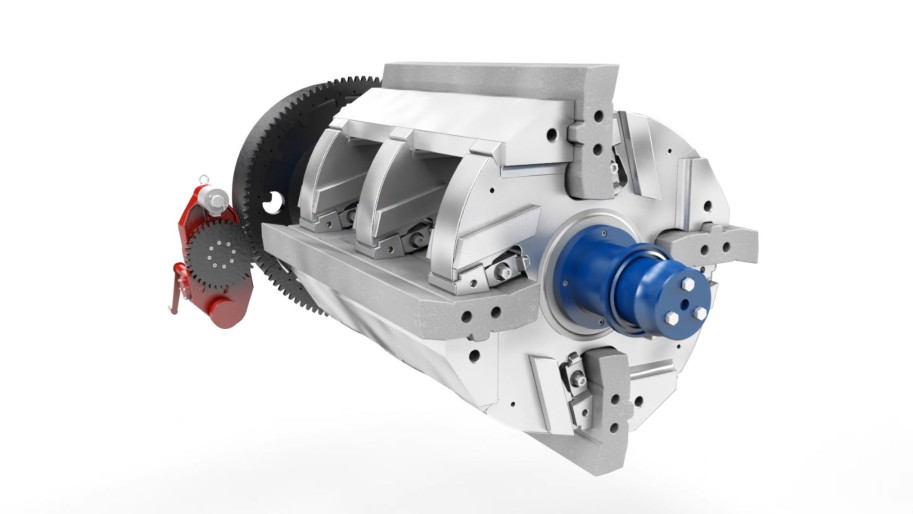

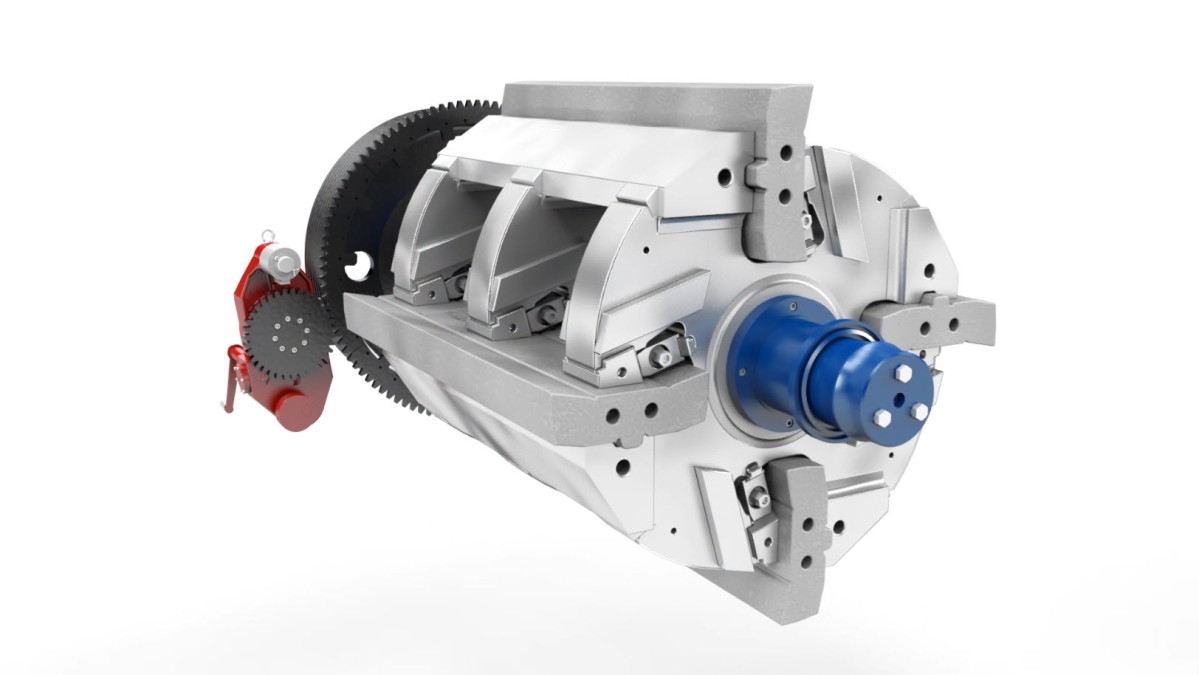

- Crusher drive type

- Crusher inlet (W x H)

- Crusher weight (approx.)

- Crusher capacity

- Impact crusher type

- Rotor diameter

- Type of impact toggle adjustment

-

- Crusher drive type

- direct

- Crusher inlet (W x H)

- 1,300 mm x 900 mm

- Crusher weight (approx.)

- 16,500 kg

- Crusher capacity

- 310 kW

- Impact crusher type

- SHB130-090

- Rotor diameter

- 1,200 mm

- Type of impact toggle adjustment

- stepless, fully hydraulic

- Crushing capacity for demolished concrete up to approx.

- Crushing capacity for mixed rubble up to approx.

- Crushing capacity for demolished asphalt up to approx.

- Crushing capacity for limestone up to approx.

-

- Crushing capacity for demolished concrete up to approx.

- 300 t/h

- Crushing capacity for mixed rubble up to approx.

- 300 t/h

- Crushing capacity for demolished asphalt up to approx.

- 260 t/h

- Crushing capacity for limestone up to approx.

- 340 t/h

- Width x length

-

- Width x length

- 1,400 mm x 2,700 mm

- Discharge height approx.

- Width

- Length

- Length, extended

-

- Discharge height approx.

- 3,650 mm

- Width

- 1,400 mm

- Length

- 9,700 mm

- Length, extended

- 11,300 mm

- Drive concept

- Power supply unit output

- Power pack manufacturer

- Generator

-

- Drive concept

- D-DRIVE (Diesel-direct)

- Power supply unit output

- 368 kW

- Power pack manufacturer

- Scania

- Generator

- 135 kVA

- Discharge height, fine grain discharge conveyor, approx.

- Width x length approx.

- Type

- Return conveyor width

- Return conveyor length

- Return conveyor, extended, width

-

- Discharge height, fine grain discharge conveyor, approx.

- 3,580 mm

- Width x length approx.

- 1,550 mm x 4,550 mm

- Type

- Single-deck light-piece screen

- Return conveyor width

- 500 mm

- Return conveyor length

- 9,750 mm

- Return conveyor, extended, width

- 650 mm

- Transport height approx. (standard value)

- Transport length approx.

- Transport length with secondary screening unit approx.

- Transport width approx.

- Transport width with secondary screening unit max.

- Transport weight of basic plant approx.

- Transport weight max. configuration approx.

- Transport weight of screening unit approx.

-

- Transport height approx. (standard value)

- 3,750 mm

- Transport length approx.

- 18,385 mm

- Transport length with secondary screening unit approx.

- 21,620 mm

- Transport width approx.

- 3,000 mm

- Transport width with secondary screening unit max.

- 3,150 mm

- Transport weight of basic plant approx.

- 49,500 kg

- Transport weight max. configuration approx.

- 64,500 kg

- Transport weight of screening unit approx.

- 6,500 kg

All details, illustrations and texts are non-binding and may include special equipment. We reserve the right to make technical changes without prior notice. Performance data are dependent upon actual operational conditions.