Battery-powered electric tandem rollers in the compact class

HAMM presents its first fully electric battery-driven tandem rollers. The models form part of the HD CompactLine series and will initially be available for the European market. Some models are fitted with oscillation drums, including the world's first e-combination rollers featuring oscillation. Not only is compacting with these models emission-free, it's also ultra-quiet.

Zero-emissions energy-efficient compacting

With eight electric rollers in the compact class, HAMM's launch represents a milestone for the compaction industry. The HD 10e model (drum width: 1.00 m, operating weight: 2.5 t) and the HD 12e model (drum width: 1.20 m, operating weight: 2.7 t) boast the same compaction power as their combustion engine counterparts, but produce zero emissions. The e-rollers are operated in exactly the same way as the other models in the HD CompactLine series.

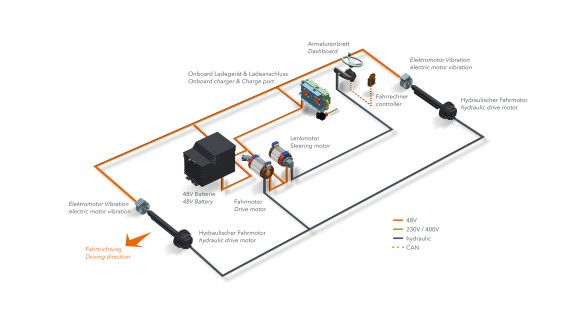

Low-voltage system delivers energy for a whole day

One Li-ion battery (capacity 23.4 kWh) provides the energy for the travel, steering, and vibration or oscillation drives via a 48-V system. Staff do not require any specialist training or qualifications to operate the low-voltage system. The battery can be charged via a rapid-charge plug (400 V, CEE) or a standard plug (230 V, earthed adapter). To charge the battery from 0% to 100% takes approx. 4 hours (400 V) or approx. 7.5 h (230 V). The battery is designed to operate in ambient temperatures of up to 45 °C and provides enough energy for one typical work day.

Energy-saving drives

The vibration or oscillation unit is driven by electric means only via specially designed, compact synchronous motors. As a result, the efficiency rating more than doubles and the energy demand reduces accordingly too. The electric drive motor and steering motor power a hydraulic system. All e-components require no maintenance and offer impressively high torque. The concept ensures the power is always available to deliver peak performance on demand. Furthermore, a large portion of the braking energy is fed back into the system by means of regeneration.

HAMMTRONIC on board

The HAMMTRONIC control system monitors and controls the components of the zero-emissions rollers. Combined with the electronic driving levers, this makes the machine extremely easy to control with precision. Speed ramping is also implemented to ensure smooth accelerating and braking manoeuvres.

Sustainable overall concept

HAMM has fine tuned every aspect of the e-rollers to preserve resources. For example, the models feature an automatic electric motor stop as standard. This deactivates all functions when the machine is idling, thereby reserving precious battery capacity. When ECO mode is selected, the control limits the working speed. This also saves energy, as does the LED lighting, which is fitted as standard. The innovative steering control also helps to conserve energy: In the parking position, it uses no energy at all. The steering motor does not switch on until the electric driving lever is actuated. Then the machine steers with sensitive responsiveness and an adaptive energy supply with no additional effort.

Combination e-rollers with oscillation: For quiet and zero-emission compacting

Four of the e-models feature oscillation drums, two of which are combination rollers. This is where the already quiet oscillation meets with the quiet e-drive. The result of this is quiet compaction machines that produce no emissions and cause very few vibrations in the surrounding area. They are ideal for compacting in noise-sensitive and vibration-sensitive areas, such as near hospitals or historical buildings.

Low maintenance

All electrical components in the e-rollers are completely maintenance-free. The extensive electrification reduces the oil volume by more than 70%. Across the entire system, there are very few wear parts that need to be greased or that could suffer from abrasion. This means there are refreshingly few service points on the e-rollers compared with the diesel counterparts. The operating hours registered are also lower than on the diesel-engined models, because the operating hour meter is not activated until the driving lever is moved.

Available from 2023

At Bauma 2022, HAMM displayed two models: The HD 12e VO, a tandem roller with one vibration drum and one oscillation drum, and the HD 12e OT, a combination roller with oscillation. The first electric models are scheduled for delivery in spring 2023 to those regions where the EU Stage V exhaust emission standard currently applies. Many of these countries provide government grants to assist with the purchase of fully electric construction machinery as well as the development of the necessary charging infrastructure.

Public Relations

Reinhard-Wirtgen-Straße 2

53578 Windhagen

Germany

Tandem roller with vibration and oscillation drum

| Weight | 9,180 kg |

| Drum width | 1,680 mm |

| Exhaust emissions category | EU Stage IIIA / EPA Tier 3 |

Tandem roller with vibrating roller drum and set of wheels

| Weight | 9,160 kg |

| Drum width | 1,680 mm |

| Exhaust emissions category | EU Stage IIIA / EPA Tier 3 |

Tandem roller with two vibrating roller drums

| Weight | 10,965 kg |

| Drum width | 1,680 mm |

| Exhaust emissions category | EU Stage IIIA / EPA Tier 3 |

Tandem roller with vibration and oscillation drum

| Weight | 12,740 kg |

| Drum width | 1,980 mm |

| Exhaust emissions category | EU Stage IIIA / EPA Tier 3 |

Tandem roller with vibration and oscillation drum

| Weight | 13,045 kg |

| Drum width | 2,140 mm |

| Exhaust emissions category | EU Stage IIIA / EPA Tier 3 |

Tandem roller with two vibrating roller drums

| Weight | 9,655 kg |

| Drum width | 1,680 mm |

| Exhaust emissions category | EU Stage IIIA / EPA Tier 3 |

Tandem roller with vibration and oscillation drum

| Weight | 9,680 kg |

| Drum width | 1,680 mm |

| Exhaust emissions category | EU Stage IIIA / EPA Tier 3 |

Tandem roller with two vibrating roller drums

| Weight | 12,570 kg |

| Drum width | 1,980 mm |

| Exhaust emissions category | EU Stage IIIA / EPA Tier 3 |

Tandem roller with two vibrating roller drums

| Weight | 12,930 kg |

| Drum width | 2,140 mm |

| Exhaust emissions category | EU Stage IIIA / EPA Tier 3 |

Tandem roller with vibration and oscillation drum

| Weight | 10,615 kg |

| Drum width | 1,680 mm |

| Exhaust emissions category | EU Stage IIIA / EPA Tier 3 |

Tandem roller with vibrating roller drum and set of wheels

| Weight | 10,095 kg |

| Drum width | 1,680 mm |

| Exhaust emissions category | EU Stage IIIA / EPA Tier 3 |

Tandem roller with two vibrating roller drums

| Weight | 10,530 kg |

| Drum width | 1,680 mm |

| Exhaust emissions category | EU Stage IIIA / EPA Tier 3 |

Tandem roller with vibrating roller drum and set of wheels

| Weight | 8,585 kg |

| Drum width | 1,680 mm |

| Exhaust emissions category | EU Stage IIIA / EPA Tier 3 |

Tandem roller with vibration and oscillation drum

| Weight | 7,960 kg |

| Drum width | 1,680 mm |

| Exhaust emissions category | EU Stage IIIA / EPA Tier 3 |

Tandem roller with vibrating roller drum and set of wheels

| Weight | 9,230 kg |

| Drum width | 1,680 mm |

| Exhaust emissions category | EU Stage IIIA / EPA Tier 3 |

Tandem roller with two vibrating roller drums

| Weight | 9,190 kg |

| Drum width | 1,680 mm |

| Exhaust emissions category | EU Stage IIIA / EPA Tier 3 |

Tandem roller with two vibrating roller drums

| Weight | 1,590 kg |

| Drum width | 800 mm |

| Exhaust emissions category | EU Stage V / EPA Tier 4 |

Tandem roller with two vibrating roller drums

| Weight | 1,680 kg |

| Drum width | 1,000 mm |

| Exhaust emissions category | EU Stage V / EPA Tier 4 |

Tandem roller with two vibrating roller drums

| Weight | 2,515 kg |

| Drum width | 1,000 mm |

| Exhaust emissions category | MEE IV |

Tandem roller with vibrating roller drum and set of wheels

| Weight | 2,435 kg |

| Drum width | 1,000 mm |

| Exhaust emissions category | MEE IV |

Tandem roller with two vibrating roller drums

| Weight | 4,420 kg |

| Drum width | 1,380 mm |

| Exhaust emissions category | MEE IV |

Tandem roller with vibrating roller drum and set of wheels

| Weight | 4,100 kg |

| Drum width | 1,380 mm |

| Exhaust emissions category | MEE IV |

Tandem roller with two vibrating roller drums

| Weight | 7,445 kg |

| Drum width | 1,500 mm |

| Exhaust emissions category | EU Stage IIIA / EPA Tier 3 |

Tandem roller with two vibrating roller drums

| Weight | 2,755 kg |

| Drum width | 1,200 mm |

| Exhaust emissions category | MEE IV |

Tandem roller with vibrating roller drum and set of wheels

| Weight | 2,655 kg |

| Drum width | 1,200 mm |

| Exhaust emissions category | MEE IV |

Tandem roller with vibration and oscillation drum

| Weight | 7,625 kg |

| Drum width | 1,500 mm |

| Exhaust emissions category | EU Stage IIIA / EPA Tier 3 |

Tandem roller with vibrating roller drum and set of wheels

| Weight | 7,190 kg |

| Drum width | 1,500 mm |

| Exhaust emissions category | EU Stage IIIA / EPA Tier 3 |

Tandem roller with two vibrating roller drums

| Weight | 7,795 kg |

| Drum width | 1,680 mm |

| Exhaust emissions category | EU Stage IIIA / EPA Tier 3 |

Tandem roller with vibration and oscillation drum

| Weight | 7,975 kg |

| Drum width | 1,680 mm |

| Exhaust emissions category | EU Stage IIIA / EPA Tier 3 |

Tandem roller with vibrating roller drum and set of wheels

| Weight | 7,465 kg |

| Drum width | 1,680 mm |

| Exhaust emissions category | EU Stage IIIA / EPA Tier 3 |