MULTI JET fuels

Efficiency and sustainability in energy production

For any burner designed as a single-fuel burner in its standard version, for the drying and heating of the base material, there is the option of extending this burner to up to three fuels. This conversion turns the burner into a combined burner and permits the use of a wide range of fuel variants. This means that oil, natural gas, liquid gas, standard gaseous materials like DME and hydrogen, and even solids like coal dust, BtL and wood dust can all be combined together.

This kind of flexibility offers numerous benefits. On the one hand, this eliminates plant downtime that can result from a lack of raw material or delivery problems. On the other, the least-expensive fuel can always be selected in the event of price fluctuations affecting a particular fuel. In additional, the flexible use of alternative fuels also enables zero-carbon drying. Thanks to these enhancements, the burner can make an important contribution to efficiency and sustainability in energy production.

Switching from fossil to carbon-neutral fuels

All over the world, climate action and tougher regulations from state and local governments are also challenging the asphalt industry to reduce its output of greenhouse gases like CO₂. Owners of asphalt mixing plants have to reduce emissions to help secure the future of the plant site. When it comes to mixing asphalt in a cleaner and more sustainable way, changing from oil or coal dust to gas is a major step: using natural gas or liquid gas already halves carbon emissions.

Results for the renewable fuels wood dust and biomass to liquid is even more impressive: these fuels are carbon-neutral, while hydrogen is carbon-free*. The fuels of the future are also attractive when it comes to their availability, as fossil fuels are not only limited, but are becoming increasingly more difficult to produce. This makes it even more important for plant owners to have the right technologies for using alternative fuels and to therefore be ready for the future.

* Energy-intensive thermal drying and heating process of virgin and recycled material, carbon-free thanks to green hydrogen.

“We are always thinking ahead and developing solutions for tomorrow. Apart from allowing the use of future fuels such as wood dust, BtL and hydrogen, we also focus on direct energy savings.”

Steven Mac Nelly, Head of Development & Design Engineering at BENNINGHOVEN

Fuel: heating oil EL

Oil burner for light heating oil (heating oil EL)

Heating oil made from crude oil is classified as one of two types: extra-light heating oil (fuel oil EL) and heavy fuel oil (fuel oil S). The quality requirements for heating oil are defined in DIN 51603. Light heating oil can be burned in furnaces, central heating systems and industrial firing plants without preheating. Heavy heating oil, on the other hand, has to be preheated for transport and combustion. The systems run with these fossil fuels, however, are increasingly subject to regulations and restrictions.

Fuel: gas

Liquid gas burner and natural gas burner

The BENNINGHOVEN gas burners can use liquid gas as a fuel when it is in the liquid phase, without first having to transform it into a gaseous state. This means that no extra peripheral equipment like an evaporator is needed, also avoiding the need for additional energy input.

Liquid gas burners and natural gas burners have the same mechanical structure. They differ only in the peripheral equipment, i.e. how the fuel is introduced into the burners.

Liquid gas, referred to as “associated gas,” is generated during the extraction of crude oil or natural gas. This associated gas used to be simply released into the atmosphere or burned in many cases. Today, more and more regions worldwide have banned burning, which has an additional positive impact on the increasing availability of liquid gas.

Fuel: hydrogen

Hydrogen drying system from BENNINGHOVEN

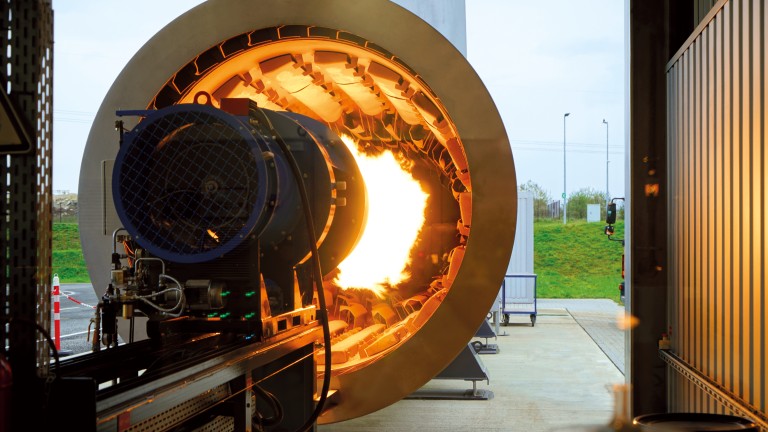

GAME CHANGER – the burner generation that can also use 100% green hydrogen

* Energy-intensive thermal drying and heating process of virgin and recycled material, carbon-free thanks to green hydrogen.

Find out moreFuel: wood dust

Still burning in the future

Wood is a renewable resource which can be produced sustainably and is therefore carbon-neutral when used as a fuel. With the MULTI-JET wood dust burner, BENNINGHOVEN has made it possible to burn wood dust in asphalt mixing plants – adding another product to the portfolio of burner technologies developed in-house. For plant owners, wood dust burners are a sustainable option for setting their plant up for the future.

The development engineers at BENNINGHOVEN have identified the ideal particle size for wood dust, which is produced mainly from scrap wood and wood waste. Identifying the optimum grading curve for the fuel is important for the flame geometry of the burner – and therefore for the effectiveness of heating the virgin mineral or the recycled asphalt (RAP). Several Benninghoven customers are already successfully using the MULTI JET wood dust burner.

The features of the solids burner offer the advantage that coal dust as well as wood dust can be used as a fuel.

A new burner can be adapted to coal dust as well as to the pioneering wood dust option.

But because supply issues are already emerging for coal dust now as well, wood as a carbon-neutral fuel is rapidly becoming more attractive.

The complete peripheral equipment includes the burner and dosing unit. The inlet to the dosing unit is the interface to the customer systems. The wood mill and the wood silo are provided by the customer.

Burner

The wood dust is fed into the burner with precision dosing by means of the feed fan and the dosing unit. In the burner head, a separate pilot flame then ignites the material. The control range for wood dust with pilot flame is 1:6; the calorific value of wood dust is approx. 18 MJ/kg depending on the type of wood.

The secondary fuel is used for the pilot flame, e.g. heating oil EL, liquid gas or natural gas.

The wood dust dosing system with storage tank has a capacity of 2.5 m³ and is installed at the discharge of the wood dust silo. In the tank, two agitators prevent the formation of bridges in the wood dust. A speed-controlled dosing screw releases the fuel in accordance with the required burner output and transports the wood dust into a blow-through rotary valve, which forms the interface to the conveying pipe. From there, the wood dust is blown into the head of the burner with a feeder fan and pipe.

Starting material on the asphalt mixing plant

The owner is obligated to ensure that the overall plant (for example the silo with the dosing system) is checked as part of a regular inspection as per the German industrial safety regulations (BetrSichV). Outside of Germany, the systems are subject to mandatory testing – the applicable national laws and directives must be observed.

Explosion protection (ATEX) especially for coal dust and wood dust

Fuel: BtL (biomass to liquid)

Energy from biomass

The principle of producing BtL fuels is based on liquefying biomass.

In the case of wood as a starting material, thermo-chemical conversion processes in a reactor use high temperature and high pressure to turn the cellulose-rich wood into pyrolysis oil.

The further processing steps include cleaning, synthesis and refining of the pyrolysis oils to produce BtL fuels

Another significant development in the energy market is the use of liquefied biomass, known as biomass-to-liquid (BtL). BtL can be produced from plant waste such as straw, wood or energy crops like maize and oilseed rape. For the use of biomass as a fuel, BENNINGHOVEN now also offers an innovative

solution: the MULTI JET BtL burner. Like wood dust, biomass-to-liquid is also considered carbon-neutral. And like all MULTI JET models, BENNINGHOVEN BtL burners can also be run with other fuels such as oil, coal dust and gas. The new BENNINGHOVEN burners therefore offer plant operators a future-proof investment option: continuing to use fossil fuels in the short term while being ready to switch to renewable fuels quickly.

For wood or wood waste as a starting product, the challenge lies in the processing of the natural material that can vary greatly in its chemical composition. These fluctuations affect the final BtL product. Smaller fluctuations can be compensated for by adapting the preheating temperature. In the case of greater fluctuations or fuel changes, the settings have to be changed on site.

For new fuels, customers send their heating medium to Wittlich in a stainless steel container so that the correct basic burner parameters can be determined at the BENNINGHOVEN factory. There, the fuel is tested extensively and the optimum burner settings are identified.

Fuel: coal dust

Coal dust burner (brown coal or hard coal)

The BENNINGHOVEN MULTI JET burner, which is designed as an oil burner in standard models, can be expanded to utilize up to three other fuels. This turns the burner into a combination burner, which means that other types of fuel such as oil, natural gas, liquid gas, heavy oil, BtL fuels (liquefied biomass) and coal dust are all available as fuels. The lignite dust is fed into the conveying pipe with the aid of the coal dust dosing system (flange-mounted onto the outlet valve of the coal dust silo) and blown into the head of the burner by a conveyor blower.

This well-designed coal dust dosing system offers operators a number of key benefits:

Working more efficiently with sustainable and economical technologies is the challenge of today and tomorrow. Benninghoven offers a variety of innovative solutions for increasing sustainability in asphalt production.

Find out moreAsphalt production, recycling systems, combustion technology, control systems, and bitumen technologies – thanks to BENNINGHOVEN’s technologies, each of our customers can find the right solution for their specific site that fully complies with requirements and conditions.

Go to technologies