WPT Crushing:

Optimizing processes digitally

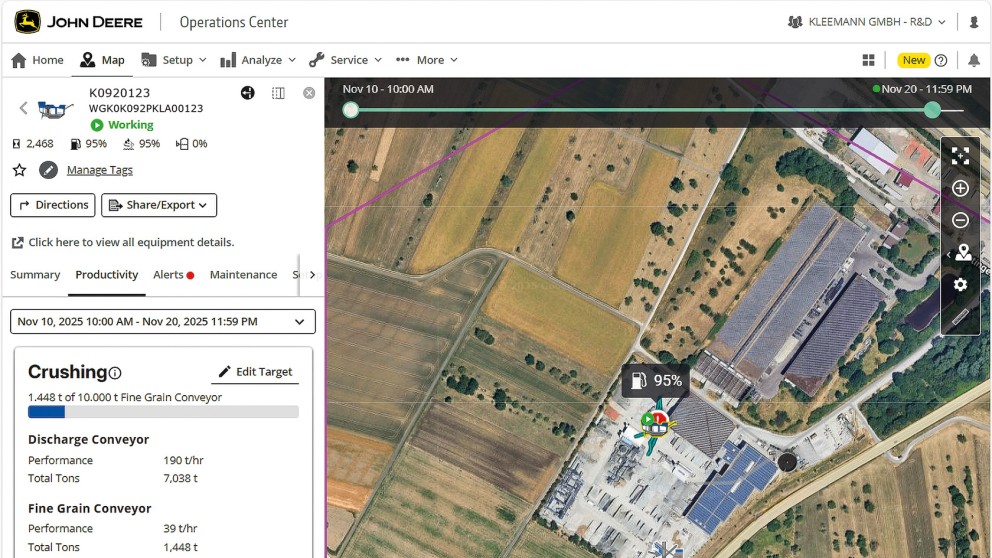

Whether in the quarry or in recycling – it is important to monitor and control the crushing process efficiently. WPT Crushing displays key figures in real time on the screen in the office. This allows the crushing process to be monitored and conclusions to be drawn for optimization. Machines equipped with WPT Crushing provide data on performance directly to the John Deere Operations Center™ – the central telematics platform for work site management of the Wirtgen Group.

Measuring and documenting machine performance – this is the strength offered by WPT Crushing. The system delivers live performance data on the crusher – at all times and everywhere. The measurement data is continuously evaluated and clearly presented to users. WPT Crushing thus delivers valuable information on ongoing work site projects. With long-term use, the system can contribute to increased productivity, efficiency, and quality on every single work site.

Simplify sequences, increase productivity

The advantage are numerous: Planning is simplified, production progress can be monitored remotely, and it is possible to respond more quickly to production downturns. An operator of several plants can transparently compare their efficiency at different locations – without even making a phone call. “The benefits for the user are truly comprehensive,” says Jörg Schaudig, Product Manager for Digital Solutions at Kleemann. “Users can make decisions based on data and facts. This allows conclusions to be drawn about which machine settings lead to which results, thereby optimizing crushing performance. All in all, efficiency and profitability are increased.”

Technical prerequisites

In order that WPT Crushing can supply reliable data, different components must be installed on the crusher. On the one hand, the hardware: the belt scale with belt speed control and a weighing cell for the conveyor belt. The conveyor belt scale measures the belt load on a defined section of the belt, while the speed sensor records the speed of the moving conveyor belt. A GPS and mobile radio aerial installed at the plant guarantees data transmission. In addition, there is the MTG (telematics unit), which acts as a communication and processing device and is standard on all supported Kleemann plants.

Maintenance and care of the components are extremely simple. For example, regular calibration via SPECTIVE TOUCH user interface or with SPECTIVE CONNECT is easily accomplished in seven guided steps using a mobile device. Recalibration is necessary at certain intervals when the plant is in operation, after setup functions, or due to environmental influences. Regular calibration ensures measurement accuracy.

Continuous data measurement

Production data is recorded every second, transmitted via mobile communications, and processed and available in the cloud within a few minutes. The satellite connection also allows the exact position of the plant to be viewed at any time, providing an optimal overview of the work sites – even from a distance. System openness was also taken into account: Thanks to the standardized AEMP 2.0 interface, standardized machine data can already be transferred to company-owned software today. Crushers already in operation with a Wirtgen Group telematics unit (TCU) of the previous generation can be retrofitted at any time with WPT Crushing.

“Users can make decisions based on data and facts. This allows conclusions to be drawn about which machine settings lead to which results, thereby optimizing crushing performance. All in all, efficiency and profitability are increased.”

Jörg Schaudig, Product Manager for Digital Solutions at Kleemann

Fleet management: Planning and transparency

With the use of WPT Crushing, multiple people in different roles can access the data simultaneously – from operators to site managers to senior management. For example, a fleet manager can recognize that a machine is consuming an above-average amount of diesel fuel. Comparing performance and consumption allows conclusions to be drawn about efficiency. The fleet manager can analyze operating conditions, suggest measures, and thus optimize performance.

For dispatchers, WPT Crushing with the most important performance data, is a helpful analysis tool, allowing them access to the information from any location. In companies with multiple mobile crushers in operation, production progress can be monitored at each location and bottlenecks identified at an early stage. This makes processes more transparent and decisions more informed.

Production volume and utilization at a glance

For work sites with a target tonnage, this can be visualized with a progress bar. This allows users to see at a glance when the work site is approaching its goal. “Once 80 percent of the work has been completed, the next project can be prepared and transport to the next location planned, for example. his reduces downtime and idle periods,” explains Jörg Schaudig. Those who know their plant data have a common basis for controlling and improving production.

Perfect overview of the performance data of the different belt scales and work site progress thanks to WPT Crushing.

Various users benefit from WPT Crushing

Production volume, utilization, project planning – these are the most important parameters that you can keep your eye on WPT Crushing. But even areas where the advantages are not quite so obvious benefit from the data: For example, service and maintenance work can be optimized. If lower tonnages are suddenly measured, this can be an indication of wear. This means that wear parts supply and service calls can be planned in advance before production downtimes occur. Similarly, the service life of the crushing tools installed can be determined and evaluated on the basis of tonnage rather than operating hours alone. The findings help in procuring the optimal wear parts.

Further applications: Shift supervisors notice that performance declines during the course of the day. They check the process and notice that the feed material has changed. By adjusting the machine settings, performance is stabilized during the current shift.

Operators can also use the data to demonstrate compliance with environmental and sustainability targets. This allows CO₂ emissions per ton to be calculated using the figures for plant performance and diesel consumption.

The results from WPT Crushing can even form the basis for decisions on future investment and new acquisitions: long-term performance data, cost-benefit analyses – the data from the Operations Center shows how efficiently individual plants operate, which plants prove themselves, and which perform better than others.

WPT Crushing – the benefits at a glance

Efficient combination: WPT Crushing and John Deere Operations Center™

Machines equipped with WPT Crushing and the John Deere Operations Center™ work perfectly as a team. The main features of the digital telematics platform include planning, monitoring, maintenance, and analysis of work sites and machines. The integrated maintenance plans and data-based recommendations for action enable comprehensive process, machine, and service optimization. The platform can be accessed anytime, anywhere, both via the web and via mobile devices.