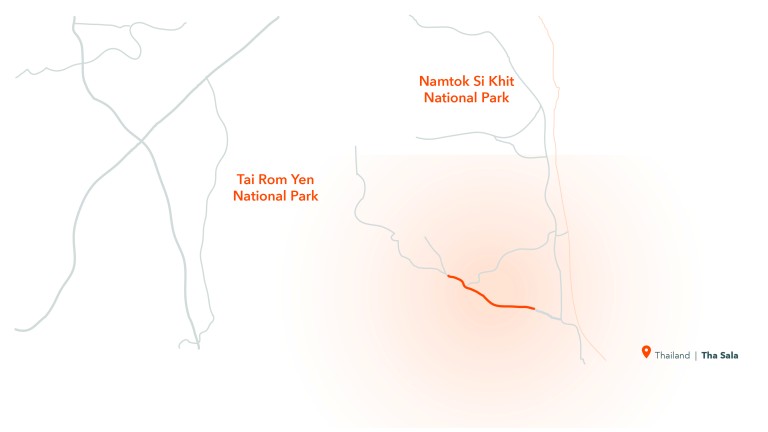

Project Site 1 – Surat Thani

Precision over a distance of 22.3 kilometers: Construction contractor Premium Concrete is realizing a road construction project with an overall length of 22.3 kilometers in Thailand’s Surat Thani province. The new section is a part of the important AH2 trunk road to Maluan.