With its machinery fleet, which also includes various milling machines, pavers and rollers from the Wirtgen Group, PBS is successful in its home region as well as in the neighboring Zakarpattia Oblast region.

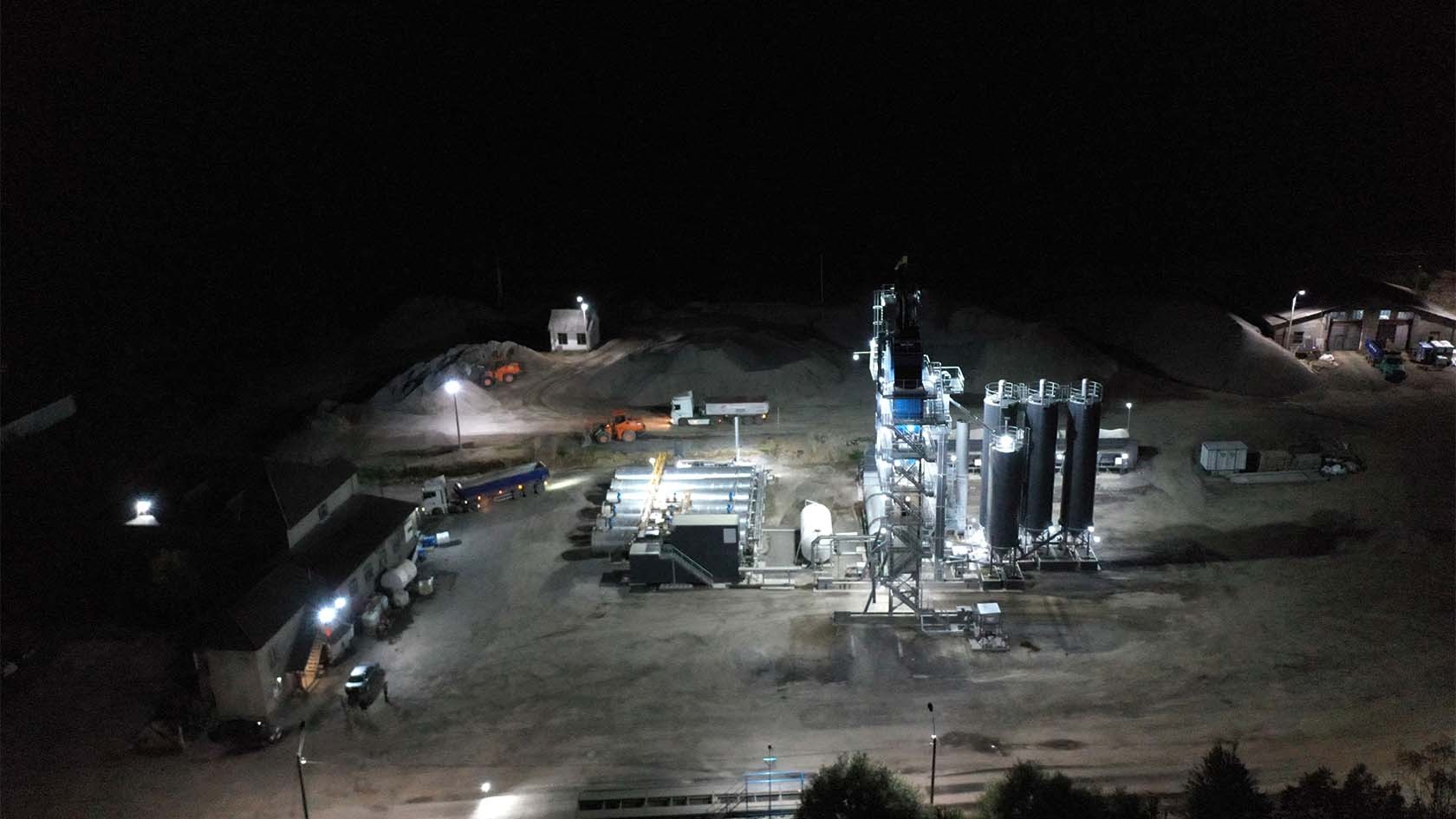

For building and refurbishing the roads in the region, which is characterized by numerous mountain roads with many bends and bridges, the construction company has now also invested in a Benninghoven asphalt mixing plant type ECO 3000.