Base layer rehabilitation with a CR series machine

The cost-efficient alternative to traditional road rehabilitation methods saves time and money, and simultaneously reduces CO₂ emissions

In Markt Indersdorf, around 50 km north of Munich, cutting-edge technology works hand-in-hand with sustainability in the road construction process chain. Here, paving contractor SSP Seizmeir Straßen- und Pflasterbau GmbH produced a new base layer in just 3 days using a cold recycler from the CR series – and not only cut the construction time by 6 to 8 weeks, but also significantly reduced the burden on local taxpayers.

Germany’s road systems are plagued by an enormous backlog of planned or pending rehabilitation projects – especially in the case of communal traffic infrastructure. The reasons for this are high traffic density, adverse weather conditions, and long construction times. Traditional road rehabilitation methods are often pushed to the limit when it comes to cost-efficient project realisation. The costs of material and site logistics are high, construction times are long and the environmental footprint is often anything but ideal.

With in situ cold recycling, Wirtgen offers a pioneering alternative that is cost-efficient, resource-friendly, and quickly achieveable– a solution that also ideally fulfils the road construction requirements of regional, local and communal authorities.

A cold recycling train, consisting of a W 240 CRi, a Streumaster SW 16 MC, a John Deere JD 672 GP Grader, two Wirtgen milling machines W 150 CFi and W 130 Fi, a Vögele Super 2100-5i paver and several Hamm rollers.

For the rehabilitation of the ST 2045, paving contractor SSP Seizmeir Straßen- und Pflasterbau GmbH from Scheyern relied on a CR series cold recycler with foamed bitumen technology. Here, hot bitumen is foamed by the addition of precise amounts of air and water and added to the mixing process together with small quantities of a pre-spread cement binder. As a rule, the surface course layers, made up of asphalt or granular material, are taken up and mixed with binding agents in a single pass. In the mixing chamber of the CR, the foamed bitumen forms fine micro-bonds within the material. These bonds are decisive for ensuring the long-term elasticity of the BSM (Bitumen Stabilized Material) used as a new base layer.

The material is transferred directly from the CR to the material hopper of the Vögele paver and laid down as the train advances. Here in Markt Indersdorf, with an impressive production rate of 360 tonnes per hour. No transportation of material away from the site, no intermediate stockpiling, and no need for new base layer mix – simply uncomplicated, fast and resource-friendly.

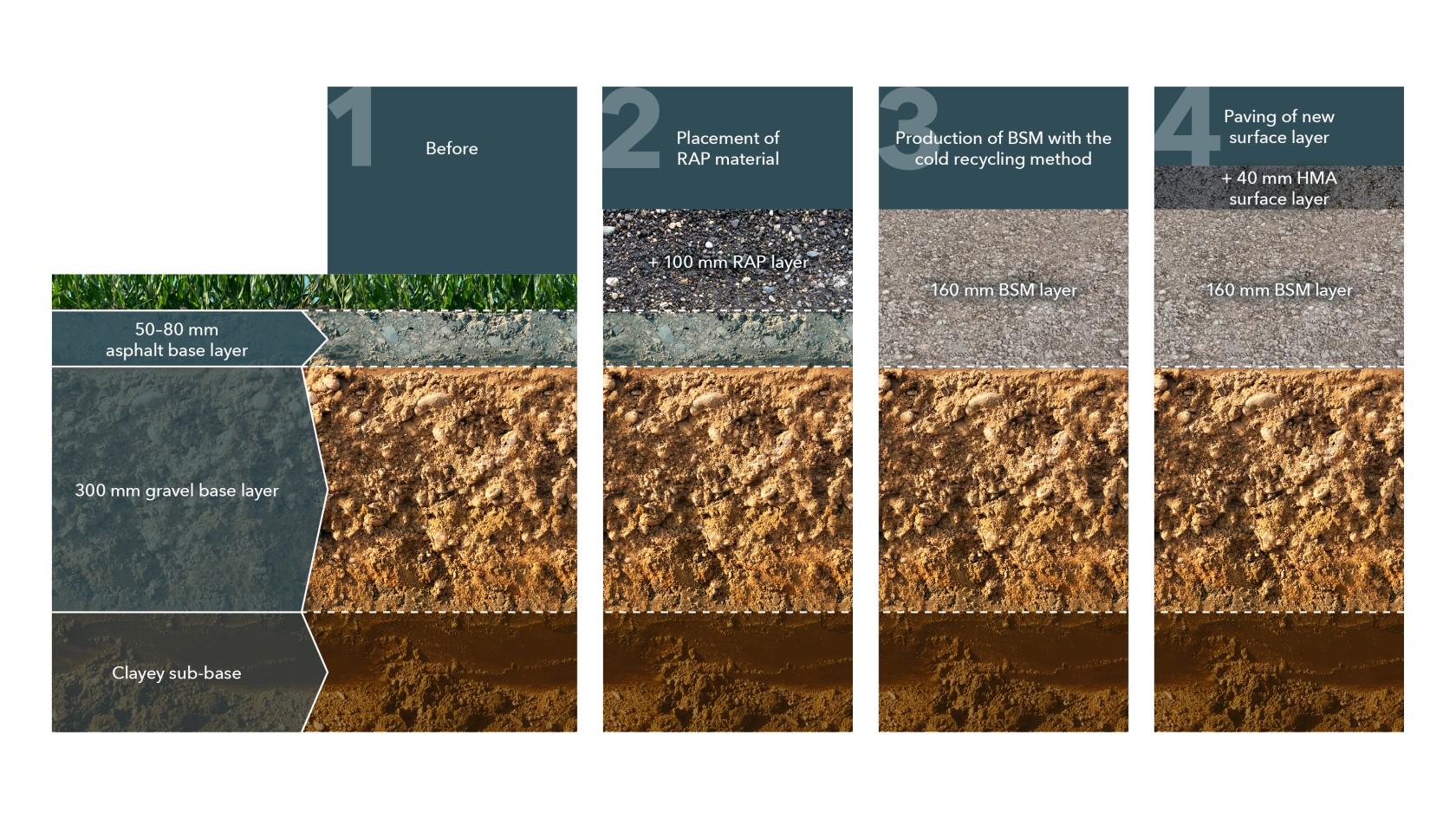

The materials were tested in the construction materials laboratory before the start of the project to find the ideal recipe for the new base layer. In the course of this, it was determined that the existing 50 – 80 mm asphalt surface layer would be insufficient for the desired end result.

In view of this, additional reclaimed asphalt pavement (RAP) from nearby construction sites was mixed in during the cold recycling process to produce the desired 160 mm BSM base layer.The 100 mm layer of RAP augments the existing asphalt surface layer and, together with the cement binder and foamed bitumen, is a further ingredient of the mix for the new base layer of the road.

The result: a homogeneous, bitumen stabilised base layer – almost entirely without the addition of new construction materials.

The entire construction project was realised exclusively with cutting-edge Wirtgen Group technology.

Preparation:

Cold recycling:

Surface layer paving:

‘This saves us a whole load of material trucking. It’s a big advantage that we can turn the material into a new and better base layer right here on the site.’

Stefan Hausmann, Senior Site Engineer at SSP Seizmeir Strassen- und Pflasterbau GmbH

The existing base layer consisted of the round gravel typically used in this region – a material that was assessed as unsuitable for inclusion in the cold recycling process. The CR and the milling machines milled down precisely to the upper boundary of the gravel layer. This meant that the road bed would remain untouched and the new 160 mm base layer would be augmented. The now thicker layer structure thus increases the load-bearing capacity of the road. In the final step, the BSM base layer was paved over with an only 40 mm thick surface layer of new asphalt. ‘We are now rehabilitating the road with the cold recycling method with a complete recycling train of Wirtgen Group machine’, explains Stefan Hausmann. ‘We are paving a new and stronger base layer with additional milled material from another construction site. The big advantage: it’s a lot faster than complete removal.’

‘We are recycling in situ and paving a better base layer with greater long-term durability than what the road has had up to now.’

Stefan Hausmann, Senior Site Engineer at SSP Seizmeir Strassen- und Pflasterbau GmbH

The entire cold recycling train works as a rolling construction site along the road, which was able to be used in front of it and behind it, even by heavy agricultural machinery. The access road to a farm, for example, was only closed off for about an hour. An advantage that cannot be overlooked in many regions.

More details and further information can be found on our product pages.

Press/media kit

Click here to download a ZIP file containing the press release in the available languages in Microsoft Word format and the images in 300 dpi resolution.

Download