Large-Scale Treatment of Non-Cohesive Soils

Soil stabilization is proving to be the optimum solution whenever the properties of soil have to be altered to make it suitable for further processing.

Soil stabilization is the method of choice for achieving the proper bearing capacity and quality of soil and preparing it for road construction projects. The targeted addition of binding agents can, for example, reduce the soil’s moisture content, which is essential for further processing. Compared to replacing all of the soil, soil stabilization is a cost-effective and resource-friendly method. Cost savings result, for example, from simpler site logistics thanks to fewer truck trips and shorter construction periods. Resources are also conserved, because all of the existing soil is used in the stabilization process with only binding agents such as lime or cement being added – or a combination of both in the form of a mixed binding agent.

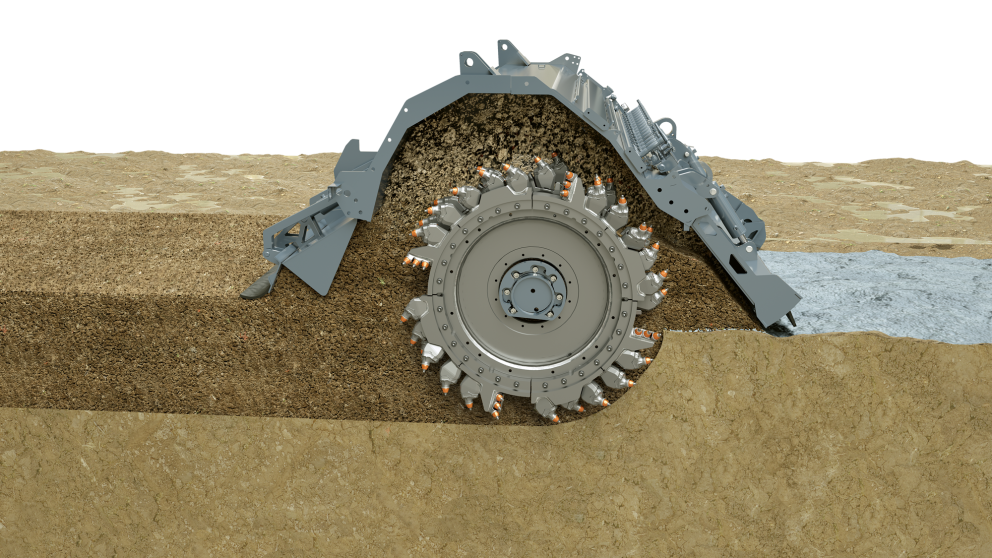

Completely replacing the soil is frequently still required in invitations to tender – but is not always necessary. The soil stabilizer uses its powerful milling and mixing rotor to mix pre-spread binding agents such as lime or cement into existing soil with insufficient bearing capacity, transforming it into a high-grade building material right on the spot. The homogeneous mixture of soil and binding agent that is produced offers a high bearing capacity as well as lasting resistance to water and frost, and volume stability. Typical applications include the construction of paths, roads, highways, routes, parks and sports fields, commercial zones, industrial parks, airfields, dams, backfilling, and landfills.

“Soil stabilizers and tractor-towed stabilizers from WIRTGEN are ideally suited for mixing soil with binding agents prior to compaction.”

WIRTGEN Soil StabilizersIn soil stabilization, a distinction is made between improving the soil and consolidating it. Lime improves the paving properties and compactability of wet, cohesive soil. This is known as soil improvement. If the objective is to consolidate the soil, cement is used because it effectively increases the bearing capacity, volume stability, and resistance to water and frost. Soil can be stabilized or homogenized even without the use of binding agents.

In order to permanently improve the properties of the soil, a series of machines are usually required. This series begins with a binding agent spreader that spreads the binding agent uniformly, followed by a Wirtgen soil stabilizer. The WR 250 uses its milling and mixing rotor to mix the soil homogeneously with the pre-spread lime. A pressurized scraper on the rear rotor plate ensures that the processed material is smoothed evenly. While a grader profiles the processed soil mixture, soil compactors ensure optimum compaction.

Stabilization with cement creates cement-treated base layers. The binding agent is spread by a towed spreader, followed by a water tanker. Behind it, the Wirtgen stabilizer’s milling and mixing rotor homogeneously mixes the soil with the pre-spread cement. At the same time, water is sprayed into the mixing chamber by means of an injection bar. Here, too, graders profile the treated material and rollers complete the job by ensuring optimum compaction.

The powerful milling and mixing rotor of the WR 250 DURAFORCE processes the pre-spread binding agent, creating a homogeneous mixture of soil and binding agent for perfect stabilization.

Product Presentation

Recyclers and soil stabilizers

Compactors