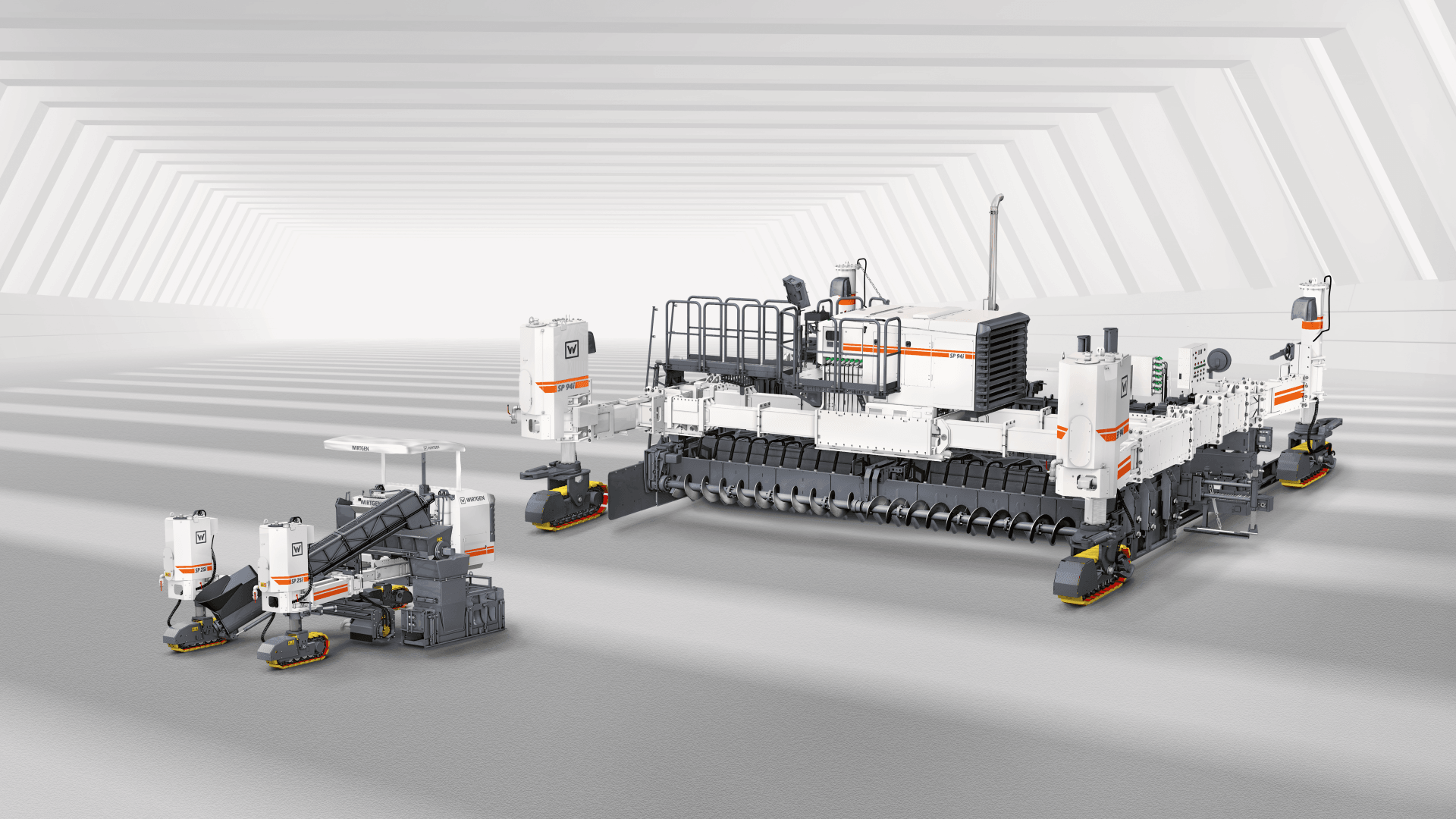

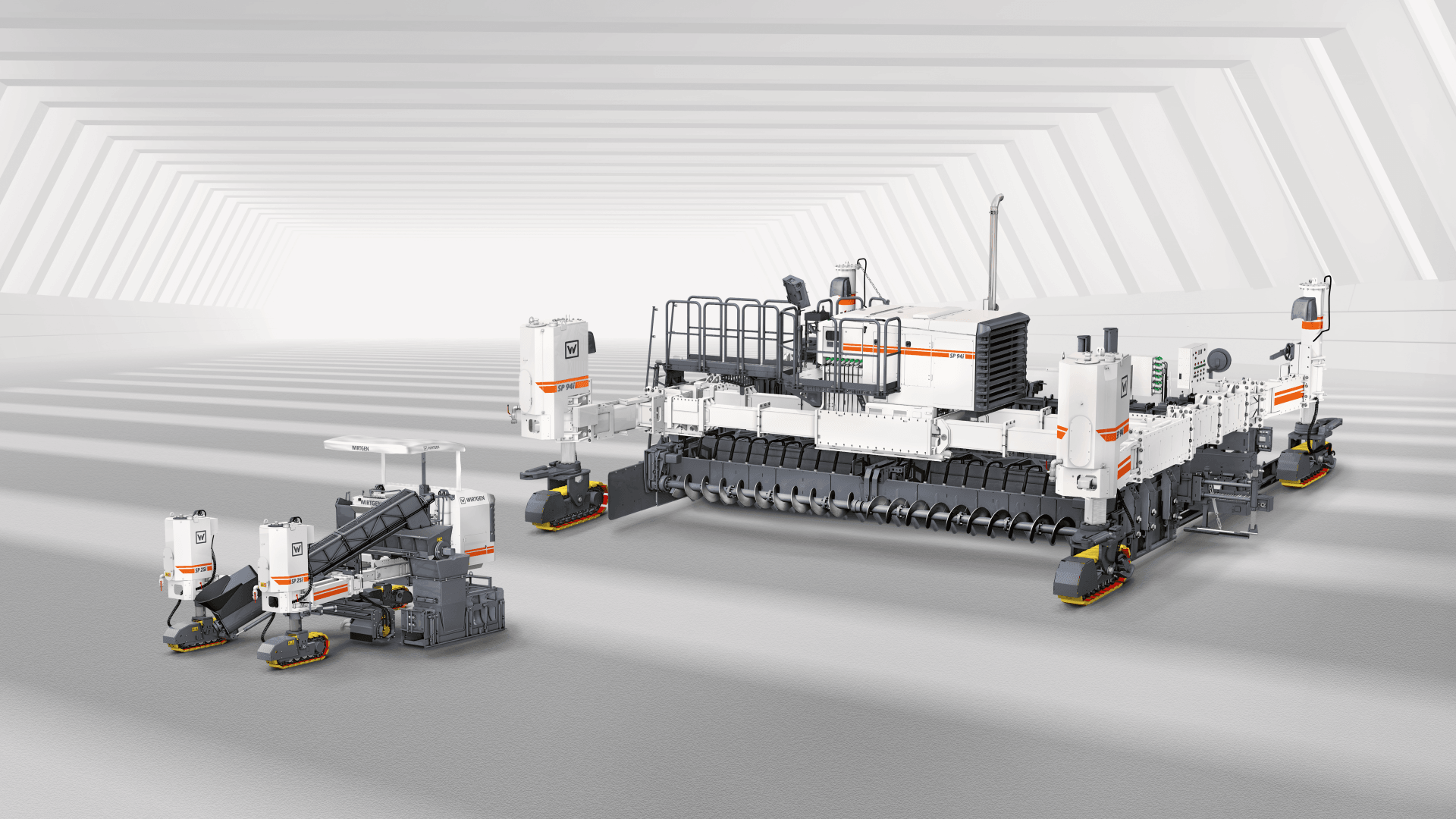

Slipform pavers

Offset pavers are used to produce monolithic concrete profiles such as protective concrete walls, kerb profiles, gutters or narrow paths. Thanks to numerous options, such as for concrete feeding or slipforming, offset slipform pavers are extremely versatile. Inset pavers cost-effectively produce concrete pavements, such as for motorways, arterial roads, runways or railway lines. In addition to single-layer concrete paving, bottom-layer and top-layer concrete can also be paved synchronously in two layers ‘wet on wet’.

With offset slipform pavers, the concrete is transported into the offset mold via a loading conveyor or a conveyor auger. The offset mold can be mounted on the left or right-hand side of the machine. A number of molds in a wide range of different shapes and sizes are available for individual applications. The offset profiles are continually produced monolithically, with or without reinforcements. Machine features include a top-quality machine control system, a practical steering and drive system and stringline-free concrete paving.

All details, illustrations and texts are non-binding and may include special equipment. We reserve the right to make technical changes without prior notice. Performance data are dependent upon actual operational conditions.