Hermann Schäfer GmbH & Co. KG is a midsize building contractor with a long and successful history. Formed in 1911, Schäfer now employs a workforce of around 120 people. For a long time now, the company has operated an asphalt mixing plant in Weilmünster, situated in Hesse’s Taunus region, which is a key supplier to road construction projects in a radius of some 100 km around the site.

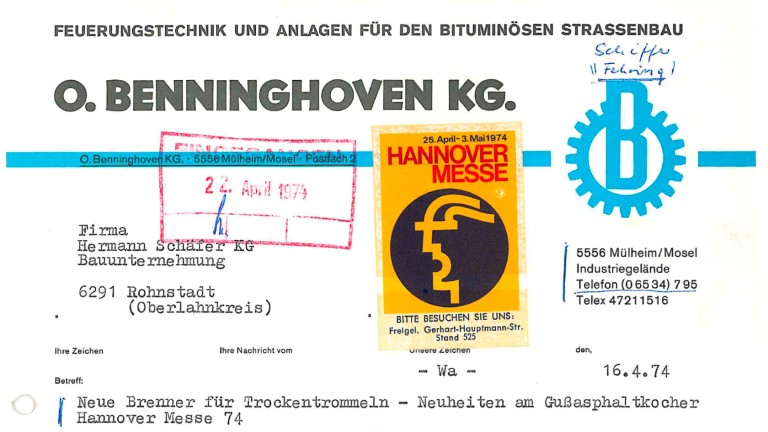

The firm’s partnership with Benninghoven started back in 1974 with a Retrofit project that added a Benninghoven burner to the asphalt mixing plant the company operated at the time. This was followed by an investment in an Benninghoven asphalt mixing plant of the TBA 3000, type, which has since produced the asphalt for both the company’s installation teams and external sales. Schäfer’s installation crews process up to 80% of the asphalt produced themselves – specifically using Vögele road pavers. The company’s machine pool also includes Wirtgen cold milling machines, which are used for renovation projects and the harvesting of recyclable material.