Wirtgen Group Unveiling World and North American Premiers at World of Concrete 2020

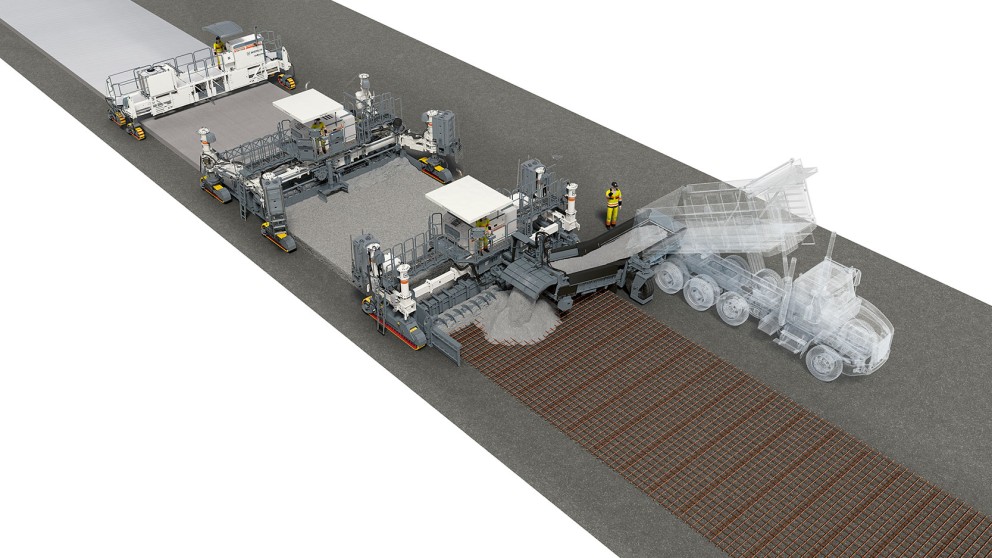

The Wirtgen Group will be presenting innovative and market-driven solutions for concrete paving at the World of Concrete from February 3 to 7, 2020. The highlight at booth C5426 will be Wirtgen’s inset concrete paving train, consisting of the two machines being unveiled at the show – the WPS 62i placer/spreader and the SP 124i slipform paver – as well as the TCM 180i texture curing machine. The small SP 25i and SP 15i concrete pavers round out the range of inset and offset solutions Wirtgen will be presenting at the show. In addition, the Autopilot 2.0 3D control system – a North American debut as well – will be demonstrated live in the outdoor area B51404.

Visitors to the trade show in Las Vegas will be the first trade audience in the world to get a glimpse of Wirtgen’s new WPS 62i placer/spreader with two track units. In the case of preplaced reinforcing steel, the concrete must be supplied from the side. Placer/spreaders like the new WPS 62i/WPS 62 are perfect for this application. As the first machine in the Wirtgen paving train, the placer/spreader passes over the reinforcement in front of the slipform paver. A truck feeds the concrete from the side, which the placer/spreader then evenly distributes over the entire working surface. The WPS 62i/WPS 62 is available with two different scraping units: in imperial units with working widths between 12 ft. and 24 ft. and in metric units with working widths from 4.00 m to 7.5 m. With both of them, the concrete can be laid up to 20 inches (500 mm) thick. Due to the fully modular machine design with standard hydraulic quick-change couplings, the WPS 62i/WPS 62 can be easily reconfigured and quickly prepared for the respective job site situation or for transport, which also increases the machine’s uptime.

With the new WPS 62i placer/spreader, the intelligent control concept of the powerful, fast folding feeder conveyor guarantees maximum concrete availability for the slipform paver following behind it.

The SP 124i/SP 124 is the first slipform paver with a working width of up to 40 ft. (12 m) that Wirtgen has equipped with four steerable and slewing crawler units. It is also available with an optional new hydraulic rotational drive system with a steering angle of up to 260 degrees. The additional maneuverability of the concrete paver allows the operator to quickly and flexibly adapt the machine to the conditions on the job site. Its narrow profile and reduced track line allows to pave close to obstacles. In addition, the four crawler units can be switched to rotation mode at the push of a button. As a result, the SP 124i/SP 124 can turn almost on the spot and directly produce the next lane in the opposite direction without wasting any time on repositioning. For transport, the swing legs are hydraulically swung in, further optimizing the transition from paving and decreasing downtime.

As the third machine in the Wirtgen paving train, self-propelled texture curing machines like the new TCM 180i/TCM 180 from Wirtgen guarantee the success of professional curing of concrete pavements. It is equipped with an automatic spraying and brooming system and directly follows behind the slipform paver to create the desired surface texture. Finally, the spraying system applies a dispersion to the fresh concrete surface, thus preventing it from drying out prematurely. The modular design of the TCM 180i/TCM 180 supports working widths between 4 m (13 ft., 1 in.) and 18 m (59 ft., 1 in).

With its newly developed AutoPilot 2.0, Wirtgen continues to be synonymous with quality and precision in concrete paving. The 3D control system can now create as many offset and inset profiles as required even more cost-effectively and precisely. In doing so, the system either uses an existing data model or creates a new digital data model on site, thereby eliminating the need for a surveyor to create a geodetic data model in advance. In addition, it also eliminates the time-consuming measuring, mounting, and removal of stringlines, making the entire operation faster and more cost-effective overall. Wirtgen offers the AutoPilot 2.0 for the SP 15/SP 15i and SP 25/SP 25i models. It is also possible to upgrade machines with the new system.

Public Relations

Reinhard-Wirtgen-Straße 2

53578 Windhagen

Germany