Rehabilitation of a combined cycle and footpath

Many pedestrians and cyclists enter Baden-Baden via the “Green Gateway” – a green corridor established for the State Horticultural Show in 1981. A SUPER 1303-3i repaved the surface course on this 3.1m-wide tree-lined route at a thickness of 3cm. The new pavement of sand-coloured asphalt blends harmoniously into the landscape. The VÖGELE wheeled paver in the Compact Class paved the coloured asphalt with a crown of 2.5%.

Germany | Baden-Baden

Working with coloured asphalt was also a special undertaking for Oliver Weiss, site manager and member of the board of directors at Weiss GmbH Tief- und Straßenbau. Firstly because coloured asphalt requires high-precision paving with no room for mistakes. Secondly because work space was extremely constricted on this tree-lined avenue. Projects like these are ideal jobs for a SUPER 1303-3i: The wheeled paver delivers a powerful performance in tight spaces.

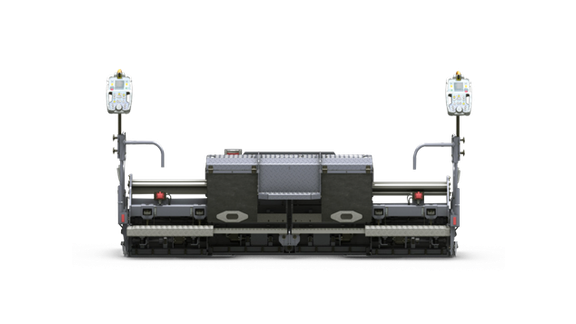

With its basic width of 1.85m and a total length of just 4.95m, the SUPER 1303-3i is extremely agile and can be manoeuvred and repositioned quickly, even on confined job sites. If Pivot Steer is activated, the outside turning circle is reduced to a maximum of 3.8m. This innovative option available on VÖGELE wheeled pavers also proved invaluable on the “Green Gateway” job site. The narrow route had to be paved in three job-site sections in addition to six side paths with several bends. The AutoSet Basic Repositioning function also assisted the paving team during the operation. All current machine data are stored at the push of a button and simply reactivated after repositioning.

The combined cycle and footpath in Baden-Baden known as the “Green Gateway” has a crown with a 2.5% slope on each side. Two HAMM tandem rollers were used for final compaction: an HD 10 and an HD 14.

Although paving coloured asphalt is a conventional process, it requires painstaking preparations. The paver’s material hopper, material handling systems and screed must be thoroughly cleaned, as must the feed lorries, to ensure that no residual black bitumen can contaminate the mix.

Needless to say, avoiding interruptions to the paving process is more important than ever. “With coloured asphalt, the crew has only one chance to get it right; the whole process has to run smoothly,” says Oliver Weiss. On confined job sites like the one in Baden-Baden, it is particularly important that the paving team can totally rely on the technology used.

On this job site, even the Compact Class VÖGELE paver needed every centimetre of available space to manoeuvre and the mix lorries faced even greater problems. It was not possible to transfer the coloured asphalt to the material hopper of the SUPER 1303-3i at every location due to the trees lining the route. The 10t hopper capacity therefore played a key role, ensuring that sufficient material was always available for continuous paving.

The VÖGELE paver’s professional material management system also helped the paving team deliver high quality results. The oscillating push-rollers ensured shock-free docking. The large conveyor tunnel, proportional control of conveyors and the powerful augers ensured an optimum flow of mix and even spreading in front of the screed.

At some points, trees along the route prevented the mix from being fed by lorry. But thanks to the 10t material hopper, it was still possible to pave continuously.

Oliver Weiss and his paving team were above all thrilled with the “machine’s responsiveness”. The SUPER 1303-3i owes its outstanding steering and manœuvrability to the proven ErgoPlus 3 operating system, which is installed in all Premium Line machines from VÖGELE. Numerous convenient and automatic functions facilitate operation from both the ergonomically designed operator’s platform and the screed operator's consoles.

Equipped with a 74.4kW diesel engine, the SUPER 1303-3i had no problem pushing the lorry in front of it while mobilizing sufficient power for the paving process. Another plus the team noticed was that the paver ran very quietly, and not just in the fuel-efficient ECO mode.

The AB 340 Extending Screed is a perfect match for pavers in the Compact Class. With a basic width of 1.8m and a maximum pave width of 5m – or 4.5m in the case of the SUPER 1303-3i wheeled paver – the screed is ideal for the construction of combined cycle and footpaths and achieves a high level of precompaction in the AB 340 TV version with tamper and vibrators.

Sand-coloured asphalt was paved as the surface course at a thickness of 3cm. The AB 340 TV Extending Screed achieved high compaction values.

The crown of +2.5% on the “Green Gateway” ensures that rainwater runs off quickly. The crown profile was set at the push of a button on one of the ErgoPlus 3 screed consoles during paving. By pressing the plus and minus buttons on the console, the operator was able to check the settings for the right and left sides of the screed on the colour display at any time.

VÖGELE’s Premium Line SUPER 1303-3i paver is the machine of choice for jobs requiring high precision in confined conditions. In Baden-Baden, however, the paving team of the experienced contractor Weiss GmbH were also overjoyed with the wheeled paver’s output and paving performance.

Wheeled paver Compact Class

| Basic width | 1.85 m |

| Pave width, max. | 4.5 m |

| Maximum laydown rate | 250 t/h |

Extending screed

| Compacting systems | V, TV |

| Pave width | 0.75 m - 5.00 m |

| Basic width | 1.8 m |