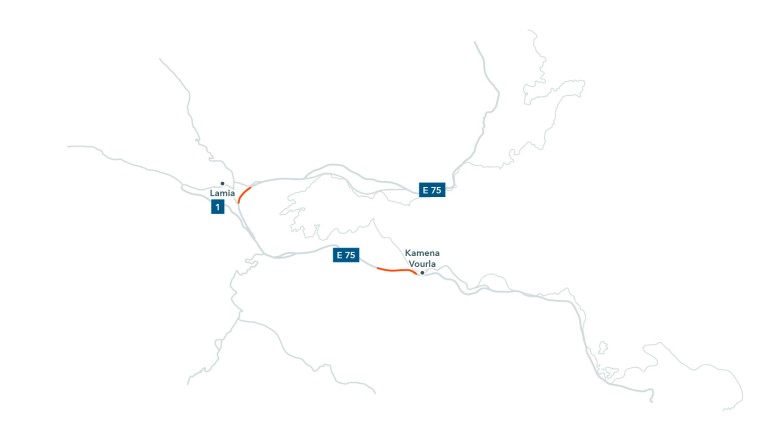

The sections of the motorway to be reconstructed, were located close to the city of Lamia and the town of Kamena Vourla are extremely busy and important traffic intersections. In all, the project involved the rehabilitation of an area of more than 50,000 m² / 540,000 sq ft of asphalt roadway in locations where complete closure would have led to absolute traffic chaos. The most efficient solution here was the use of a cold recycling train from the Wirtgen Group. Thanks to in-situ cold recycling, it was possible to reduce the construction time otherwise expected when using conventional methods by around 50% and direct the traffic flow around the rolling construction site without any problems.