Automatically Measure Milling Performance with the Wirtgen PERFORMANCE TRACKER

Wirtgen has developed a solution that, for the first time, makes it possible to accurately and reliably document actual milling work completed – the new PERFORMANCE TRACKER (WPT).

It is not uncommon for milling contractors to have to mill more than is specified in the RFP when carrying out a rehabilitation project. But how can the contractor bill the client on the basis of a transparent calculation when this occurs? Up until now, this usually involved calling in a surveying technician. The result: additional costs and delays in completing the project. The Wirtgen PERFORMANCE TRACKER, which also offers other valuable benefits, demonstrates that this can be done much more efficiently.

The Wirtgen PERFORMANCE TRACKER complements the Wirtgen Group’s WITOS telematics solution perfectly and makes milling performance transparent.

An efficient flow of information is the key to making processes easier, faster, and more cost-effective. Wirtgen refers to this as CONNECTED MILLING. This term describes the direct flow of information between the machine, operator, service workshop, and scheduling office. For this purpose, Wirtgen uses the infrastructure of the Wirtgen Group’s existing telematics solution WITOS.

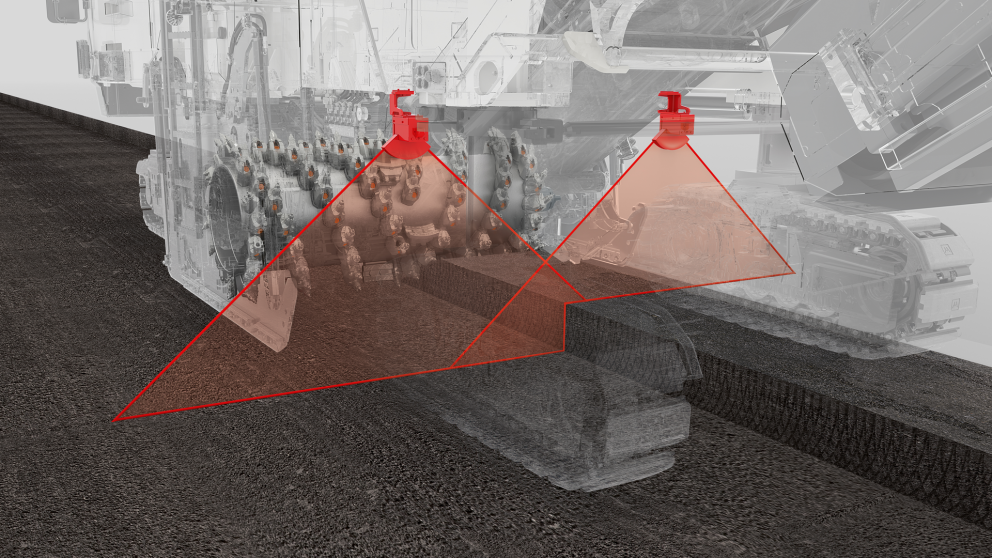

The Wirtgen PERFORMANCE TRACKER uses a laser scanner to measure the cross-sectional profile to be milled. Surface milling performance and milling volume are then precisely measured using GPS positioning and other sensors. The machine operator can continuously track the most important information in real time on the control panel’s display. After completing the milling work, a report with all of the relevant performance and consumption data is generated automatically in Excel and PDF format and sent to the machine operator by e-mail.

In addition to the new F series, all Wirtgen large milling machines built in 2010 or later can be retrofitted with the PERFORMANCE TRACKER.

In addition to the documentation feature, which allows milling jobs to be billed quickly and on the basis of transparent information, the Wirtgen PERFORMANCE TRACKER can also be used to precisely determine site costs. For example, the accurately measured performance and consumption data not only makes it easier to evaluate the efficiency of current and future construction sites. In addition, the data can be used to easily compare the machines with other cold milling machines in the machine fleet – a valuable basis for the machine operator to decide which milling machine is the most efficient solution for which job.

The Wirtgen PERFORMANCE TRACKER complements the Witos FleetView telematics system perfectly and makes milling performance transparent.

In addition to the new F series, Wirtgen large milling machines built from 2010 onwards and already in operation can also be equipped with the PERFORMANCE TRACKER. Thanks to intelligent hardware and software solutions, it is possible to retrofit these machines at Wirtgen Group locations within a single day.

Public Relations

Reinhard-Wirtgen-Straße 2

53578 Windhagen

Germany