HC CompactLine series – the new compacts for earthworks

HAMM presents new small compactors: The HC CompactLine series (EPA Tier 4/EU Stage V engines) replaces the predecessor H CompactLine series with immediate effect. The new compacts offer impressive gradeability, improved driving characteristics and a comfortable, spacious cab. The 5 t and 7 t machines are extremely easy to operate and offer ergonomically optimized workstations. This also makes them ideal for machine rental.

Powerful drive

Thanks to the HC 50i (5 t, drum width 1.37 m) and HC 70i (7 t, drum width 1.68 m), the HC CompactLine series comfortably meets the requirements for compact earthwork rollers. Permanent all-wheel drive with anti-slip control and drive motors instead of a rear axle form the basis for exceptionally good gradeability and high ground clearance. The developers have also further improved and stabilized the handling with various adjustments to the chassis.

Short climbers

Both compactors are extremely short. In particular, the HC 70i is the world's shortest compactor in this weight class, at 4.40 metres. Combined with the 3-point articulation and the extremely short wheelbase, this results in very good driving and handling characteristics, ideal for compaction on narrow construction sites.

Easy operation

No specific language skills are required to operate the HC CompactLine. The logical arrangement, careful design and clear symbols on the operating elements make manual operations straightforward. The backlit display ensures unambiguous operation, even in the dark. The arrangement of the steering wheel allows a clear view of and easy access to the dashboard.

Good visibility, safety and comfort

In terms of visibility, the small compactors offer very wide fields of vision in the open version or large window areas in the cab. A camera system with a monitor can also be added. High-quality LED work lighting is included as standard in the cab. All models in the HC CompactLine series offer convenient access to the ROPS/FOPS cab or to the open platform with ROPS, which is available with or without a protective roof and with the option of adding FOPS. The generous space offered by the completely redesigned cab with specially curved windows is unique in this market. In terms of ergonomics, the operator also benefits from the versatile adjustable seat system and a seat that can be moved to the side, wide-opening windows and draught-free ventilation. There are also plenty of storage areas, an optional USB connection and comfort options such as a tiltable steering column and an air-conditioning system.

ECO mode reduces fuel consumption

On the small compactors, a modern Kubota engine (55.4 kW, EPA Tier 4/EU Stage V) powers the drives and power units. The compactors can operate with either diesel or HVO fuel. The sustainable machine concept includes environmentally friendly and economical operation in ECO mode. This achieves savings by limiting the engine speed. The parameters have been selected so that most jobs can be done in ECO mode, without sacrificing compaction power. In addition, the optional automatic engine stop reduces diesel consumption. It automatically switches off the engine under certain conditions, e.g. during prolonged downtime. At the same time, the automatic mechanism takes into account the requirements of the exhaust gas purification with diesel particulate filter (DPF).

A variety of drums

HAMM offers compactors with smooth drums and padfoot drums with vibration. Two-piece padfoot shells can be retrofitted for the smooth drum. Accordingly, HAMM also has a specially designed combination scraper in its range. The HC 70i is also available with a VIO smooth drum that can compact either with vibration or oscillation. All models of the HC CompactLine can also have a levelling blade added.

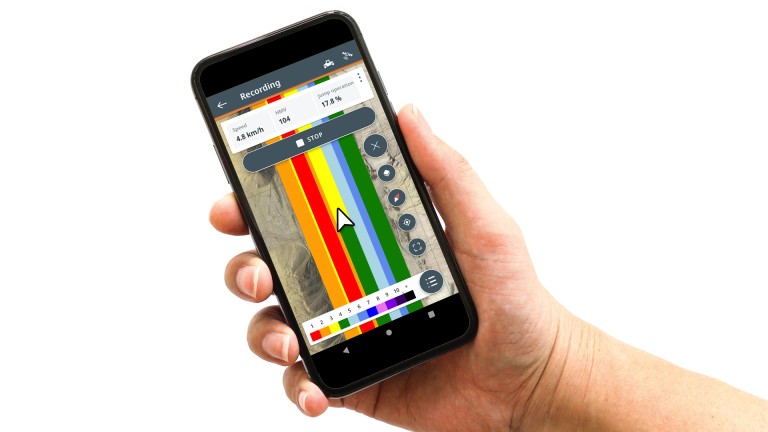

Options for compaction measurement

HAMM offers the HCM compaction meter for all models of the HC CompactLine, including rollers with VIO drums. The displayed HAMM measurement value provides a gauge for the compaction progress. HAMM has developed the "Smart Doc" app for applications that require continuous compaction control or continuous or layer-by-layer documentation. It is supplied with process data from the machine via a Bluetooth interface. The app displays the compaction status in the form of graphics on a smartphone or tablet. This enables the driver to identify where and to what degree the substrate has been compacted as they work.

Points of interest, including for rental companies

Thanks to their simple operation, multiple adjustments and numerous options, HC CompactLine rollers are ideal for rental. For example, the rear view mirrors can be easily adjusted and cleaned from the cab via split windows. Other options useful for rental companies include connection to the JD Link telematics system, the telematics interface for automated transfer of machine data, and the electronic battery isolation switch that protects against battery discharge and theft.

Public Relations

Reinhard-Wirtgen-Straße 2

53578 Windhagen

Germany