Benninghoven | Sustainability in asphalt production

Working more efficiently with sustainable and economical technologies is the challenge of today and tomorrow. Solutions from Benninghoven lower emissions and secure the future of asphalt mixing plant sites.

Benninghoven offers a variety of innovative solutions for increasing sustainability in asphalt production. Considering the entire road construction process from material acquisition and asphalt production to building the roads, companies can save up to 54 % CO₂ with these technologies. *

The intelligent Benninghoven solutions include the re-use of asphalt, the correct storage of virgin mineral and recycling material, the use of temperature-reduced asphalt, the electrification of bitumen tanks and the use of renewable energies, i.e. the fuels of the future.

*(Annual production of 100,000 t asphalt, 60 % added recycling material, carbon-neutral fuel)

Energy-efficient working while protecting resources

Sustainable operations and reduced climate-damaging emissions are the current challenges for counteracting climate change. The 2015 Paris Climate Accords, for example, require greenhouse emissions to be halved by 2030 and eliminated completely by 2050. Despite being a relatively small sector, the asphalt industry can make an important contribution to this, because asphalt production offers great potentials for reducing emissions such as CO₂ and Ctot (total carbon).

One of the control instruments for owners of mixing plants is the taxation of emitted CO₂ and emissions trading, the costs of which will increase worldwide in the years to come. The less greenhouse gases are emitted by asphalt mixing plants, the more costs can be saved. Benninghoven supports plant owners with a variety of different solutions.

Benninghoven solutions provide more energy efficiency and reduce the carbon footprint, making greenhouse savings of up to 54 % CO2 per year possible.

Module 1: reusing asphalt

Benninghoven has decades of experience with recycling reclaimed asphalt. But reusing the material is not only sustainable: The material removed by milling the asphalt during road resurfacing is also significantly cheaper than virgin mineral from a quarry. In addition to this, reclaimed asphalt already contains bitumen, which is also reused and therefore saves on the most expensive ingredient in asphalt production.

Benninghoven offers different cold and hot recycling feed systems for this, including the Benninghoven hot-gas generator – the leading recycling technology. It allows up to 100 % recycling material to be added, with low emissions. The Benninghoven REVOC system is a patented innovation that will be presented by Benninghoven at the Bauma 2022 exhibition for the first time. The new retrofit solution is a supplement for existing asphalt mixing plants equipped with one or more recycling systems and it significantly reduces the total carbon concentrations in the exhaust gas. This also makes REVOC an important contribution to securing the future the plant site.

Module 2: storing virgin mineral and recycling material correctly

Keeping the stored virgin mineral and recycling material as dry as possible is an important factor for an energy-efficient mixing process – and therefore for lower emissions such as CO₂. The following applies here: 1 % more moisture in the starting material correspond to a litre of additional heating oil or an energy equivalent for each ton of asphaltic mixture. This is one of the reasons why the German TA-Luft regulation now requires covered storage of these materials.

Roofs for dry storage of virgin mineral and recycling material save a large amount of fuel and therefore CO₂ during drying and heating of the material.

Module 3: producing reduced-temperature asphalt

The drying and heating processes for virgin mineral and recycling material are particularly energy-intensive in asphalt production. Fuel and emissions can be saved if authorities and owners use reduced-temperature asphalt types. This refers to asphaltic mixtures with a final temperature of around 120 °C. This equates to a 30 % reduction in contrast to conventional mixtures, which usually require a temperature of around 160 °C. The savings potential for energy and CO₂ is much greater, though: 18,000 kWh and 6,000 kg CO₂ are saved during the production of 2,000 t of asphalt – every day.

Benninghoven asphalt mixing plants can produce high-quality reduced-temperature asphalt in a reliable process. One important technology for this is a foam bitumen module, which Benninghoven also offers as a retrofit solution (plug & work). Foam bitumen is interesting because this binder requires only one auxiliary material for producing reduced-temperature asphalt: water, which is already available at any asphalt mixing plant anyway. Mixing hot bitumen with water multiplies the volume many times, which is why this process is also referred to as “foaming” the bitumen. The released surface energy ensures that the binder moistens the mineral very well during the mixing process even at low temperatures, temporarily generating installation properties that are comparable to those of hot asphalt.

Reduced-temperature asphalt offers a high potential for saving energy and CO₂: The key contribution comes from the production, i.e. from a Benninghoven asphalt mixing plant with the appropriate technology.

Module 4: electrifying bitumen tanks

For storing the hot bitumen – one of the most important asphalt ingredients – Benninghoven offers bitumen tanks with different capacities. These come with one or multiple chambers and can additionally be equipped with an agitator or a mixing nozzle.

The electrification results in zero local emissions – in contrast to tanks heated with thermal oil. This ensures CO₂-neutral bitumen storage in the overall balance. In addition to this, electrically heated tanks are not regulated by environmental authorities and there are no environmental restrictions.

Roofs for dry storage of virgin mineral and recycling material save a large amount of fuel and therefore CO₂ during drying and heating of the material.

Module 5: using renewable energies

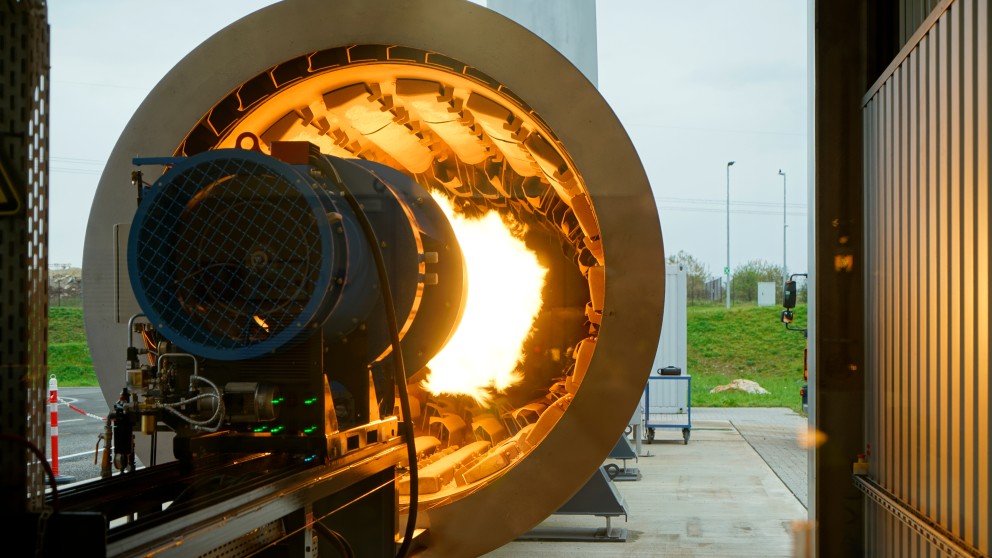

More sustainability in asphalt production means moving away from fossil fuels such as coal and oil. Benninghoven already offers the EVO JET burners which use the fuels of the future. These fuels are made from renewable raw materials and have a neutral CO₂ balance. They include biomass to liquid fuels (BtL) and wood dust. Even the complex process of burning wood dust results in a smooth flame pattern – the prerequisite for reliable operation of the plant. Benninghoven sets new standards for burner technology with its innovative solutions.

The Benninghoven technology can also be used for modern fossil, gaseous fuels such as liquid gas or natural gas. Changing from coal dust to natural gas or liquid gas already halves CO₂ emissions.

In addition to this, the Benninghoven development engineers continue to work on the sustainable and economical use of other fuel types. Using hydrogen, for example, could be an option for overcoming the challenges of the future.

Already using renewable fuels today: Benninghoven EVO JET burners can also burn biomass-to-liquid fuel (BtL) or wood dust.

Public Relations

Reinhard-Wirtgen-Straße 2

53578 Windhagen

Germany