WRC 240 X Wirtgen Rock Crusher

EU Stage 5/US EPA Tier 4f

2,320 mm

510

mm

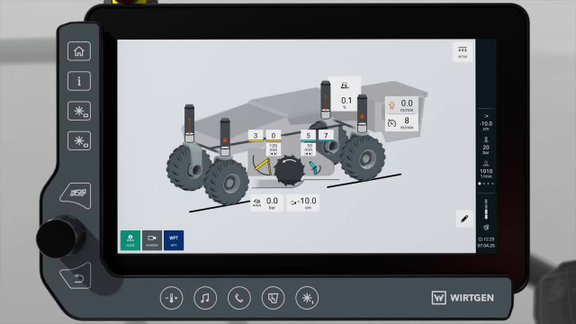

High-Performance In Situ Rock Crushing and Homogeneous Mixing

Show lessTechnical specifications

- Exhaust emissions category

- Operating and travel speed

- Working width

- Working depth

- Operating weight, CE

- Ground clearance

- Displacement

- Maximum power

- Lateral inclination, max.

- Rated power

-

- Exhaust emissions category

- EU Stage 5/US EPA Tier 4f

- Operating and travel speed

- 0 - 210 m/min (0 - 12.6 km/h )

- Working width

- 2,320 mm

- Working depth

- 510 mm

- Operating weight, CE

- 34,300 kg

- Ground clearance

- 400 mm

- Displacement

- 14.9 l

- Maximum power

- 455 kW / 618 HP 1,900 rpm

- Lateral inclination, max.

- 8 °

- Rated power

- 447 kW / 608 HP

All details, illustrations and texts are non-binding and may include special equipment. We reserve the right to make technical changes without prior notice. Performance data are dependent upon actual operational conditions.