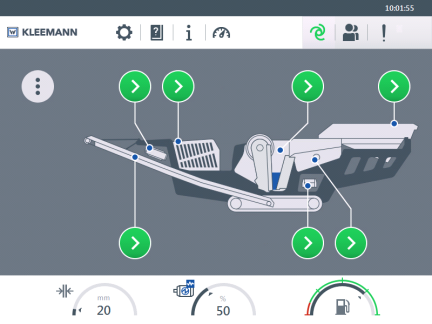

MCO 110i PRO Mobile cone crusher

E-DRIVE (Diesel-electric)

240 mm

470

t/h

Properties

The MOBICONE MCO 110i PRO mobile cone crusher stands out thanks to its extremely robust design and impressive performance. As an option, the plant can be operated via an external power source and impresses with its low-maintenance operation.

Show less Highlights

The MOBICONE MCO 110 PRO is distinguished by its extremely robust design and very high efficiency. As an option, the plant can be operated via an external power source and impresses with its low-maintenance operation.

Feeding unit

CFS

Crusher unit

Gap setting

Drive

Control system

Crusher discharge conveyor

Transport

Safety and ergonomics

Technical specifications

- Max. feed size

- Feed height

- Feed height with extension

- Feed capacity up to approx.

- Hopper width

- Hopper width with extension

- Hopper length

- Hopper length with extension

- Hopper volume

- Hopper volume with extension

-

- Max. feed size

- 240 mm

- Feed height

- 2,600 mm

- Feed height with extension

- 2,910 mm

- Feed capacity up to approx.

- 470 t/h

- Hopper width

- 1,820 mm

- Hopper width with extension

- 4,250 mm

- Hopper length

- 4,130 mm

- Hopper length with extension

- 4,130 mm

- Hopper volume

- 7.5 m³

- Hopper volume with extension

- 9.2 m³

- Width x length

-

- Width x length

- 1,200 mm x 7,500 mm

- Crusher drive type

- Crusher weight (approx.)

- Crusher capacity

- Crusher system size

- Cone crusher type

-

- Crusher drive type

- electric

- Crusher weight (approx.)

- 16,200 kg

- Crusher capacity

- 250 kW

- Crusher system size

- 1,120 mm

- Cone crusher type

- KX350

- Crushing capacity at 0-45 mm approx.

- Crushing capacity at 0-56 mm approx.

-

- Crushing capacity at 0-45 mm approx.

- 390 t/h

- Crushing capacity at 0-56 mm approx.

- 420 t/h

- Discharge height approx.

- Discharge height, extended, approx.

- Width

- Length

- Length, extended

-

- Discharge height approx.

- 3,600 mm

- Discharge height, extended, approx.

- 4,400 mm

- Width

- 1,000 mm

- Length

- 9,200 mm

- Length, extended

- 10,700 mm

- Drive concept

- Generator

- Power pack manufacturer

- Power supply unit output

-

- Drive concept

- E-DRIVE (Diesel-electric)

- Generator

- 500 kVA

- Power pack manufacturer

- Scania

- Power supply unit output

- 368 kW

- Transport height approx. (standard value)

- Transport length approx.

- Transport width approx.

- Transport weight of basic plant approx.

- Transport weight max. configuration approx.

-

- Transport height approx. (standard value)

- 3,850 mm

- Transport length approx.

- 17,595 mm

- Transport width approx.

- 3,000 mm

- Transport weight of basic plant approx.

- 49,500 kg

- Transport weight max. configuration approx.

- 58,000 kg

All details, illustrations and texts are non-binding and may include special equipment. We reserve the right to make technical changes without prior notice. Performance data are dependent upon actual operational conditions.

_PRO_Granit.jpg)