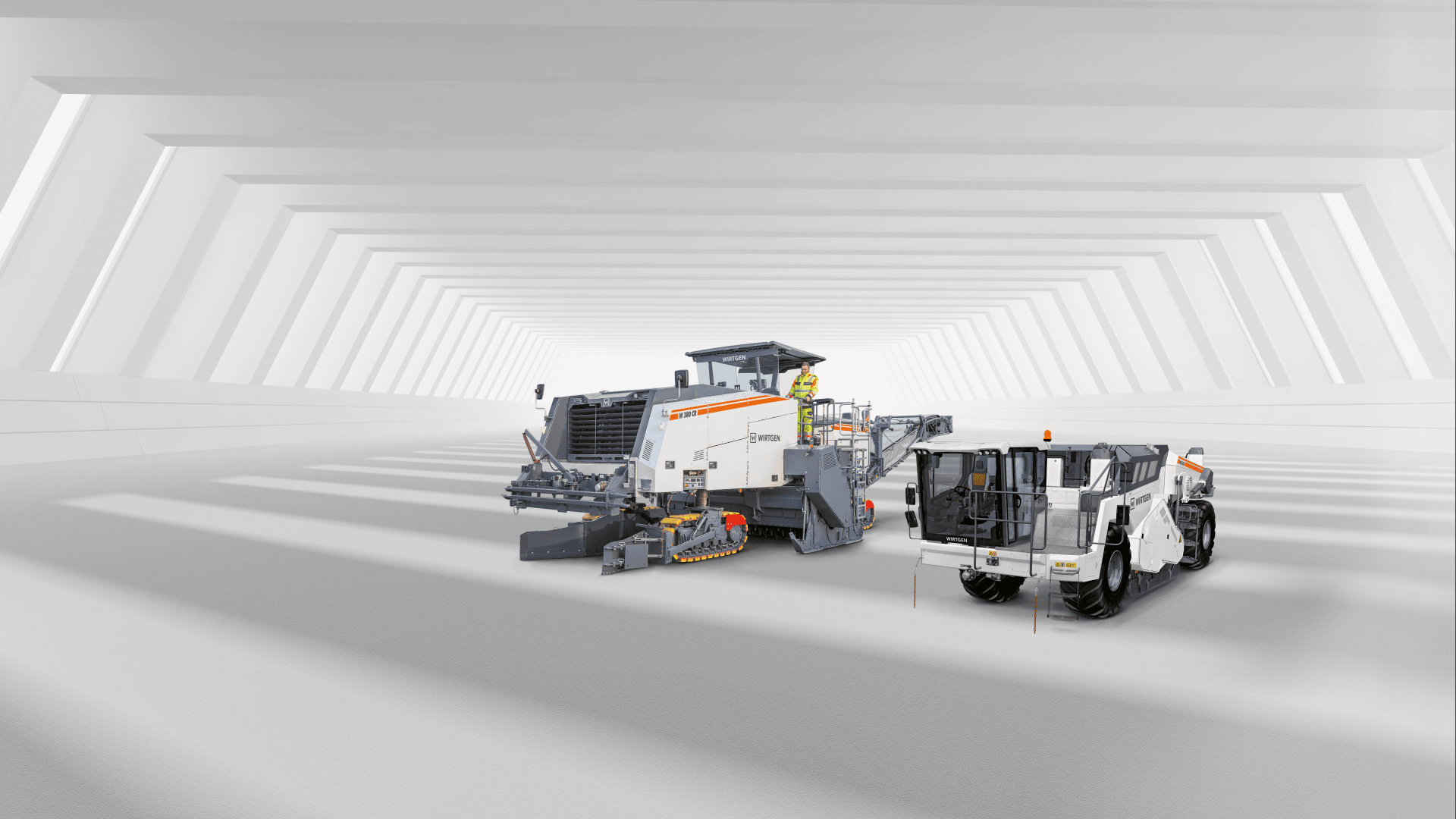

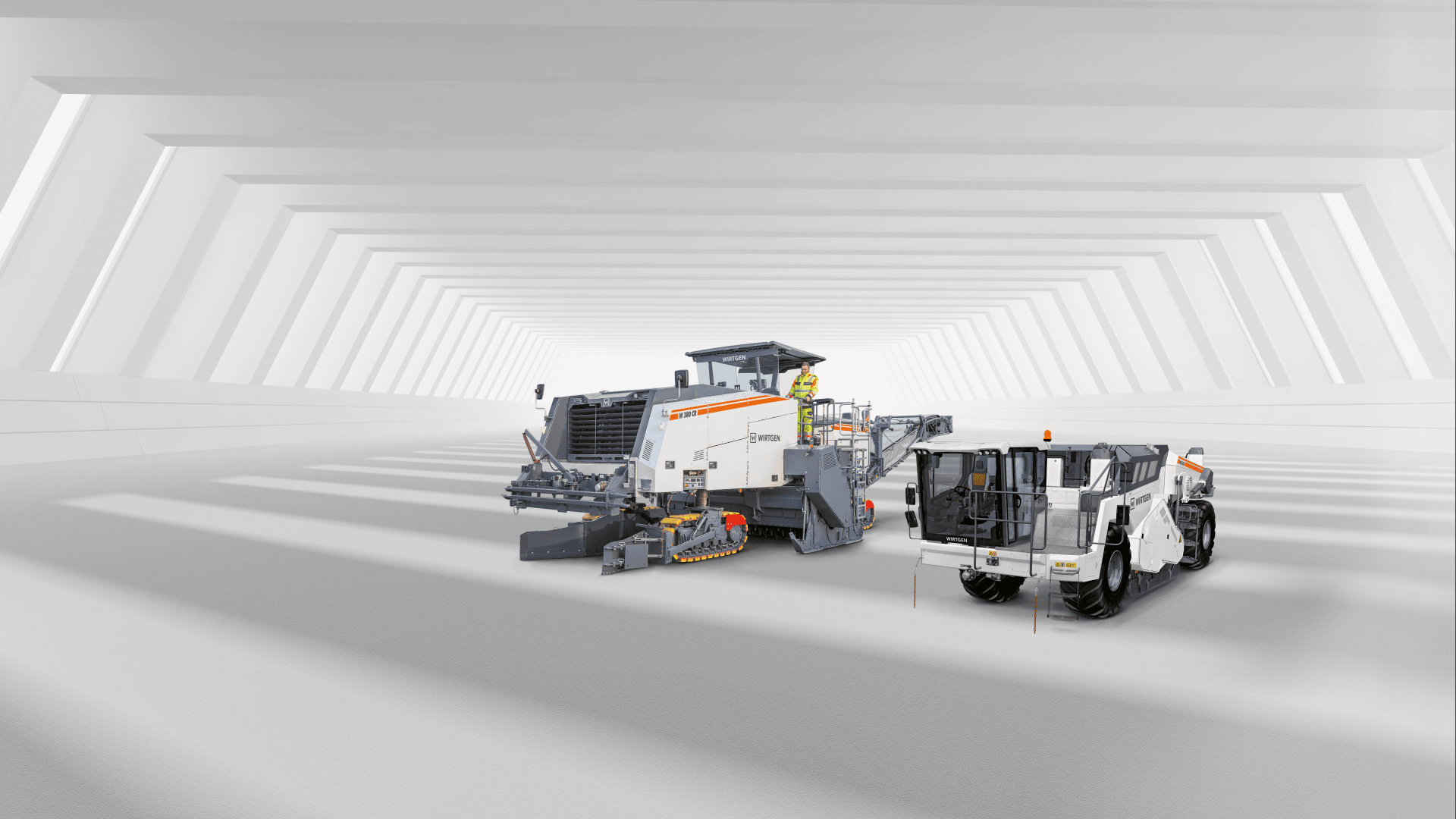

Recyclers and soil stabilizers

Cold recyclers are used to prepare asphalt pavement on site. In this process, the existing pavement is granulated with the milling and mixing rotor and prepared by adding precise amounts of bituminous binding agents, cement and water. The result is a homogeneous material that can be used to directly repave the soil. Soil stabilisers use the milling and mixing rotor to mix pre-spread binding agents such as lime or cement into the existing, less stable soil and transform it into a high-quality material directly on site.

The tractor-towed stabilizer can be attached to a tractor in a few swift moves. The adjustable rotor plate ensures the homogeneous mixing quality of binding agent and soil. Side plates which move on skids, the mechanical belt drive on each side and the effective milling and mixing rotor contribute to the high performance. In the soil improvement process, the tractor-towed stabilizer produces soils suitable for placing and compacting, while in the soil stabilization process, it creates load-bearing surfaces.

Tractor-towed stabilisers

| Working width max. | 2,500 mm |

| Working depth | 500 mm |

The recyclers have a variable mixing chamber and microprocessor-controlled injection systems for the addition of bitumen emulsion, water and foamed bitumen. In the soil stabilization process, the all-wheel drive, all-terrain machines mix binding agents into existing soils, producing load-bearing soils with ideal properties for further roadworks. In the cold recycling process, the existing pavement is milled off and the milled material is then homogeneously mixed with the added binding agents. The new mix of materials then serves as a basis for base courses.

Cold recyclers in the CR series are used for the cost-effective recycling of pavements. Binding agents and water are added in precisely metered quantities by means of microprocessor-controlled injection systems. Cold recyclers with a paving screed use the down-cut process and immediately repave the recycled construction material. In large projects requiring high daily performances, the recycler transfers the recycled construction material via its integrated discharge conveyor to the material hopper of the downstream paver, which immediately repaves it, achieving a high degree of precompaction. The recyclers in the CR series additionally can be used as high-performance milling machines.

The mobile cold recycling mixing plant is simple to transport and quick to set up in the direct vicinity of the operation site. The robust twin-shaft compulsory mixer achieves high mixing performance levels. Microprocessor-controlled injection systems for the addition of a wide range of binding agents ensure that the materials are mixed precisely to formula. The slewing discharge conveyor with its wide range of motion enables the processed cold mix to be stockpiled or continually loaded onto transport vehicles.

Cold recycling projects are multi-faceted, some even presenting a challenge. Good to be able to cover all bases. WIRTGEN provides numerous technical innovations helping you to reach your goal safely and efficiently. A range of ancillary equipment optimally rounds off WIRTGEN's unique range of cold recycling and soil stabilization machines.

Innovative laboratory equipment

| Bitumen temperature | 140 - 200°C |

| Own weight | 270 kg |

Innovative laboratory equipment

| Mixing capacity | 30 kg |

| Own weight | 220 kg |

Innovative laboratory equipment

| Impact energy, max. | 23 J |

| Own weight | 170 kg |

All details, illustrations and texts are non-binding and may include special equipment. We reserve the right to make technical changes without prior notice. Performance data are dependent upon actual operational conditions.