Several Benninghoven plants supply asphalt for Tarmac

Tarmac is a leading supplier of construction materials, including aggregates, asphalt, cement, lime and concrete, and also supports its customers in the fields of road construction and recycling. The company currently has 7000 employees at 400 sites. The flexibility offered by Benninghoven is ideal for the range of different mixing plants operated by Tarmac. It is no coincidence that all these plants were supplied by Benninghoven. One of the reasons for this is that Benninghoven plants can reliably meet a range of different requirements for the asphaltic mixtures, but also for the sustainable operation of the mixing plants. These requirements are becoming increasingly stricter in many markets, including the UK, and consequently also affect Tarmac. In addition to this, the relationship between Tarmac and Benninghoven is based on mutual trust and cooperation. “The quality of a partnership becomes particularly evident when it comes to customer service. The team of the Wirtgen Group in the UK is always ready with help and advice when we need support,” says Anthony Smith, Technical Director at Tarmac.

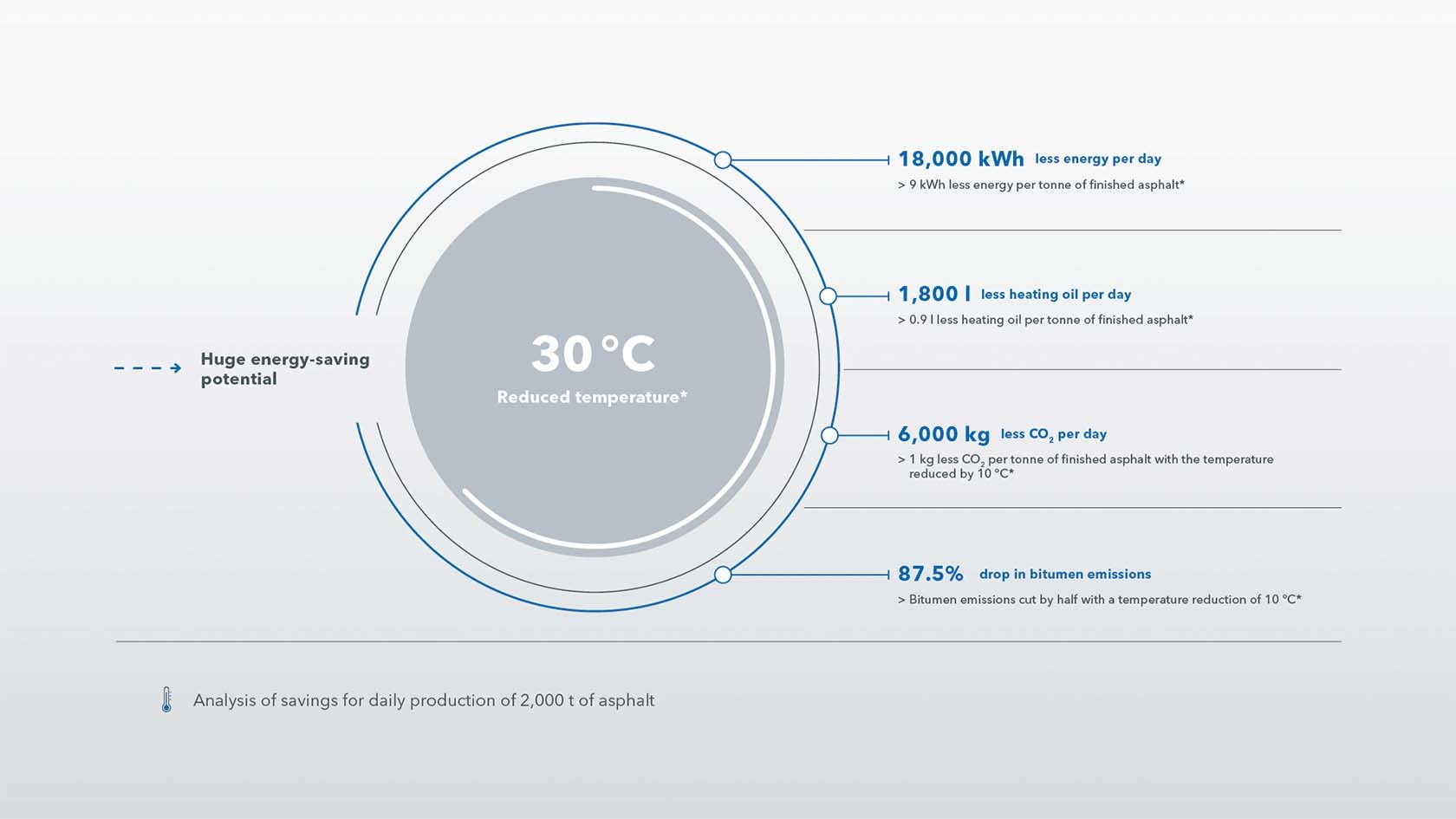

“In addition to this, the Benninghoven plants support us in our efforts to achieve sustainable and efficient operation of the plants. They conserve energy, produce less and less emissions and allow us to add increasing amounts of recycling materials,” explains Miles Dobson, Head of Production at Tarmac.