Wirtgen Group machines lay the ground

Germany's 2019 National Garden Show in Heilbronn is not set to open for another four years, but work on the exhibition grounds started back in 2014. Since early this year, machines supplied by the Wirtgen Group have been stabilizing the entire site. These include two Wirtgen tractor-towed soil stabilizers WS 250, a Hamm H 20i compactor and a Streumaster binding agent spreader SW 16 TC.

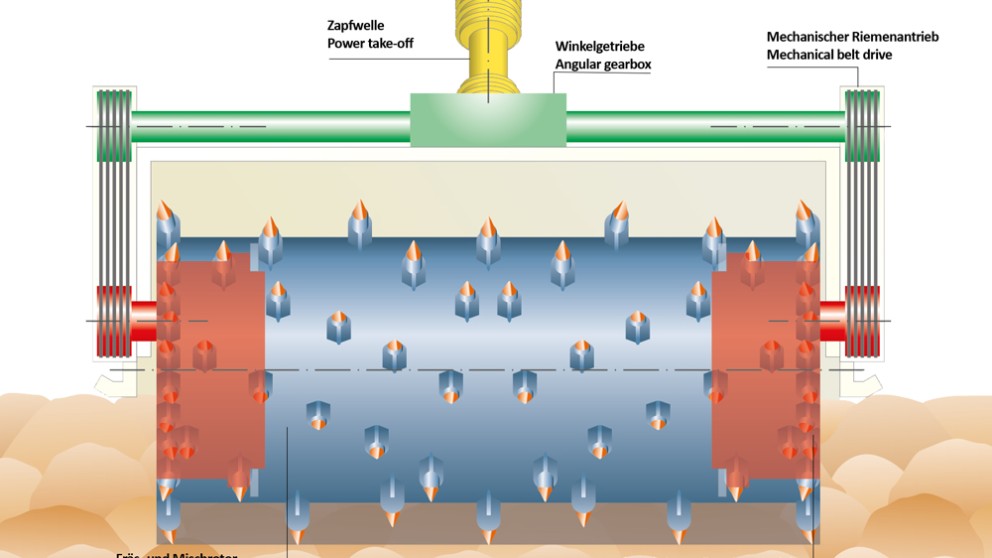

The 104 cutters on the mixing rotor relentlessly churn through the rubble-strewn ground. It looks nothing like the ideal base for a garden show. And yet in mere fractions of a second they crush concrete, stones and earth, mixing what is left with the previously spread white lime to create a homogeneous mass in a process that is audible but barely visible. Raising virtually zero dust, the tractor-mounted Wirtgen soil stabilizer WS 250 ploughs its way over the terrain. Machine Operator Marcel Stier is pleased with it: "The stabilizer never baulks at the tough conditions we're facing here. And the best thing is, it's easy to operate."

It wasn't what Stier was thinking just a few days before when two tractor-towed soil stabilizers WS 250 were delivered to the BUGA 2019 site in Heilbronn. "I'd had no experience with this type of application before and was somewhat in awe of the new machines." However, soil stabilization in particular is a key issues at the site, which is located right beside the river Neckar. As the Senior Site Manager, Philip Kircher of Wolff & Müller, a well-known German family-run construction and civil engineering company, explains: "Even before the work began in August 2014, it was clear that we needed to move huge quantities of earth on this vast 40-ha site. When you include interim storage, it amounts to an estimated one million cubic meters," says Kircher. "Replacing soil on this scale is totally uneconomical, so stabilizing it was our only option." But the process is both economical and eco-friendly. Requiring fewer machines and truck journeys as well as shorter construction times, it allows contractors to make considerable savings on resources. Furthermore, CO2 emissions are greatly reduced as well. "We obtained all the machines we needed for the job from the Wirtgen Group," adds Kircher.

While the terrain still needs to be excavated in some areas of the future exhibition grounds, elsewhere preparations for planting are already underway. "When you look at the site as a whole, we could have opted for a self-propelled soil stabilizer instead" says Wolff & Müller Branch Manager Ingolf Klärle. Indeed, the comprehensive Wirtgen product range provides the right solution for all applications. With the compact WR 200i, the WR 240i all-rounder and the WR 250 powerhouse, daily rates of between 1,000 and 12,000 m² can be achieved, depending on the condition of the ground. The high performance WR series is also superb in cold recycling applications for rehabilitating roadways economically.

However, Wolff & Müller still opted to use two tractor-towed soil stabilizers: "Since we can only work the site section by section, we can operate much more flexibly with the two WS 250s," says Klärle.

Along with the Wirtgen tractor-towed soil stabilizers, a new Streumaster binding agent spreader SW 16 TC and two Fendt tractors also arrived on site – all supplied by Wirtgen Augsburg, one of the the Wirtgen Group's four German sales and service companies. Wirtgen Augsburg and Wolff & Müller have worked together as partners for many years. Like many others, this current major project only needed a "short lead time before the machines could be dispatched on their journey to Heilbronn," says Christian Goralczyk. Goralczyk, who works in Sales at Wirtgen Augsburg, has supported the construction work ever since the applications consulting stage in the project run-up.

The construction equipment was not supplied on its own, however, but came with support from Wirtgen Group application experts. "It's all part of our service support and ensures that customers can harness all the benefits offered by our machines."

Customer service is a top priority: Wirtgen Service Technician Markus Klein (left) provides detailed instruction on operating the tractor-towed soil stabilizer WS 250 ...

As soon as they arrive on site, Streumaster Product Manager Michael Gilhuber and Markus Klein, Service Technician at Wirtgen, set to work on training machine operators, Marcel Stier and Steffen Sinn, on their new equipment. Up until then, both Stier and Sinn had only worked with tractors. While Gilhuber provides an introduction to the Streumaster SW 16 TC with its 16-m3 container capacity, pointing out its many features including the precision spreading action with the three metering feeders that can be individually controlled under load, the patented self-cleaning system and the automatic spreading quantity control, Klein explains how to operate the soil stabilizer correctly. Only after thorough instruction on the equipment do they proceed to the embankment on the western side of the site, where they start to stabilize an 800 m-long and 11 m-high section.

But first, Machine Operator Steffen Sinn needs to fill the Streumaster SW 16 TC with binding agent, a task he completes without raising any dust whatsoever, thanks to the built-in automatic dust-collecting filter system. On arrival at the embankment and after briefly maneuvring the spreader into position, Sinn starts with the precision spreading of the white lime. He is helped by the spreading quantity control system which is supplied as standard and allows between 3 and 42 l of binding agent to be applied per m2. For a pave width of 2460 mm, refills are only needed after seven 50-m passes. Thanks to the speed of the spreading process, four silo vehicles a day are dispatched from Heilbronn with a total of 106 t of white lime.

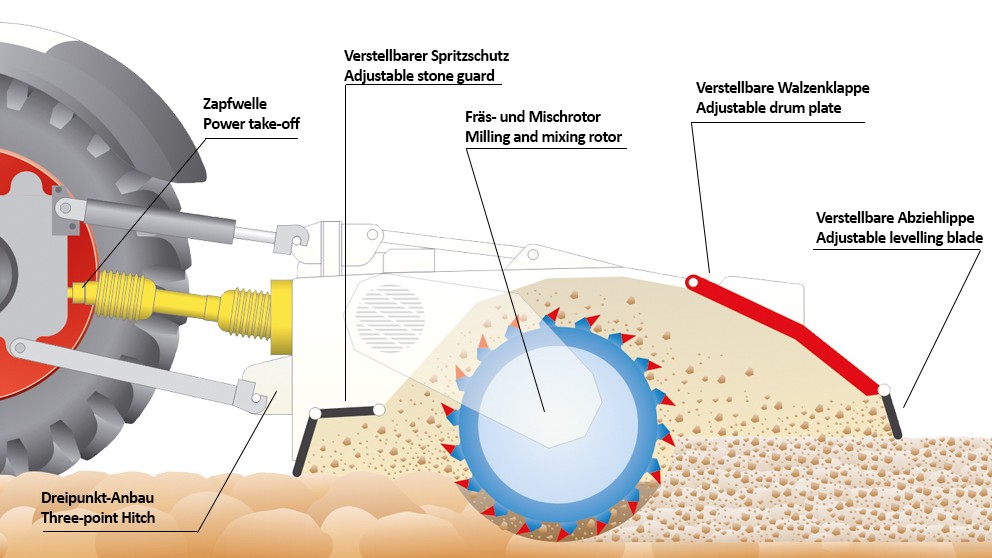

Then it's time for the binding agent to be homogeneously mixed with the soil which has an insufficient bearing capacity – and for the Wirtgen WS 250 to be deployed. Positioned on the crest of the embankment, the 2500 mm-wide mixing rotor cuts into the soil to a maximum working depth of 500 mm. At the same time, the hard rubber stone guard protects against loose chippings and minimizes the development of dust. The height-adjustable side plates are fitted with skids. These keep them above the ground and prevent them from dragging through the base, which would be an unproductive waste of power. Marcel Stier commends the smooth handling of the machine, which is due to the precise arrangement of the cutters and delivers an optimum mixing result. The stabilization process is then complete, resulting in a load-bearing, frost-resistant and water-resistant soil.

Finally, a Hamm H 20i compactor takes care of the compaction of the stabilized soil. With its driven wheels and smooth vibrating drum, the compactor can tackle even the steepest of inclines with ease. It is supported by the Hammtronic microprocessor control system, which automatically aligns the front and rear drive, thus preventing the drum and wheels from spinning. This intelligent technology also ensures economical use of consumables, making the compaction of the substrate a cost-effective process.

Even the first few stabilized sections demonstrate how the Wirtgen Group machines work together as the perfect team. Ingolf Klärle is relaxed as he monitors operations. He knows he can rely on the products and technologies of the Wirtgen Group and the support of his contact at Wirtgen Augsburg. As a result, Klärle can face the continuing soil stabilization work with equanimity and look forward to completing the works at the National Garden Show site at Heilbronn in excellent time.

Ingolf Klärle, Branch Manager, Wolff & Müller

Tractor-towed stabilizers: Making a successful start in soil stabilization

Soil stabilization has been proving its worth for many decades as an economical and environmentally friendly method. The WS 220 and WS 250 tractor-towed stabilizers from Wirtgen enable you to turn your tractor into a perfect soil stabilizer with only a few simple flicks of the wrist. The compact unit converts instable ground into high-quality construction material, improves compactability, and dispenses with the necessity of an expensive soil exchange. It impresses with its intelligent design and highly economical operation. The unit’s low weight and compact dimensions facilitate transport from one construction site to the next.

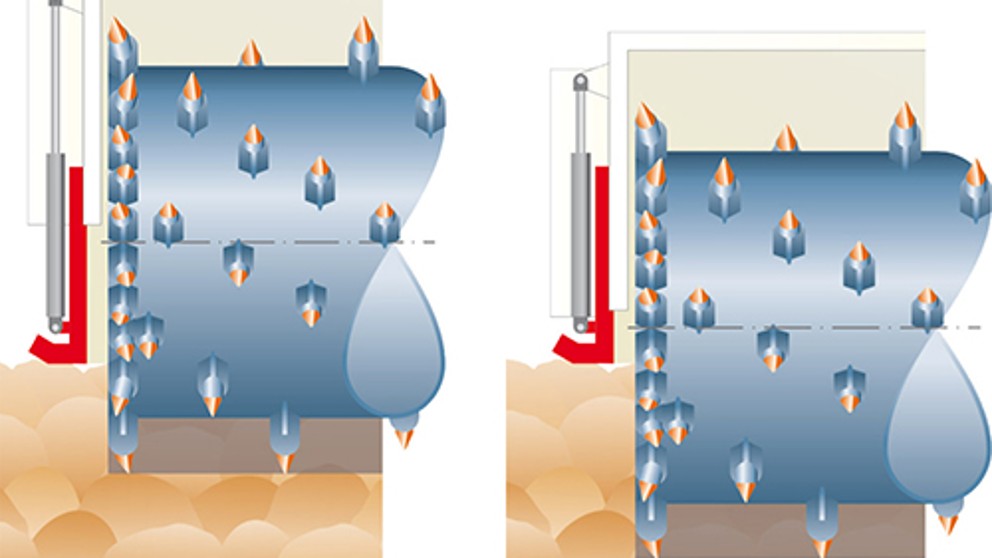

Wirtgen stabilizers are the ideal candidates also for homogenizing soils averse to compaction, such as non-uniform soil mixtures. Whether heavy, coarse-grained or sandy subgrade material: the tractor- towed stabilizer can be relied on to convert it into soil that is highly suitable for placing and compacting. If too coarse, the material to be stabilized is crushed in the mixing chamber by the milling and mixing rotor. Soft soil is covered with lime spread by, for instance, a binding agent spreader prior to treatment. Subsequent homogeneous mixing by the milling and mixing rotor causes the lime to remove the excess humidity from the soil. In earthmoving operations, soil improvement pays off in the construction of, for instance, dams or embankments, backfilling or site transport roads. Soil improvement has proved to be eminently suitable also for landfills with clay subsoils. Soil processed with suitable binding agents is practically unsusceptible to water and offers optimum conditions for further compaction

The drum plate can be precisely adjusted to any given requirements – whether low or high working depth. This contributes to the homogeneous mixing of binding agents and soil.

It happens every day: the tractor, used as a towing unit just a minute ago, needs to be converted into a soil stabilizer as quickly as possible. This requirement necessitates a simple yet practical attachment system for the milling and mixing rotor unit. Being geared to flexible and effective operation, the tractor-towed stabilizer from Wirtgen offers the ideal solution. It is attached to the tractor easily by way of a standardized three-point hitch, using the tractor’s power take-off at the same time to drive the milling and mixing rotor.

The rotor housing is additionally equipped with a variable stone guard at the front. The stone guard protects against flying stones and reduces the development of dust. The unit is adjustable in height hydraulically and can be adapted to site conditions.