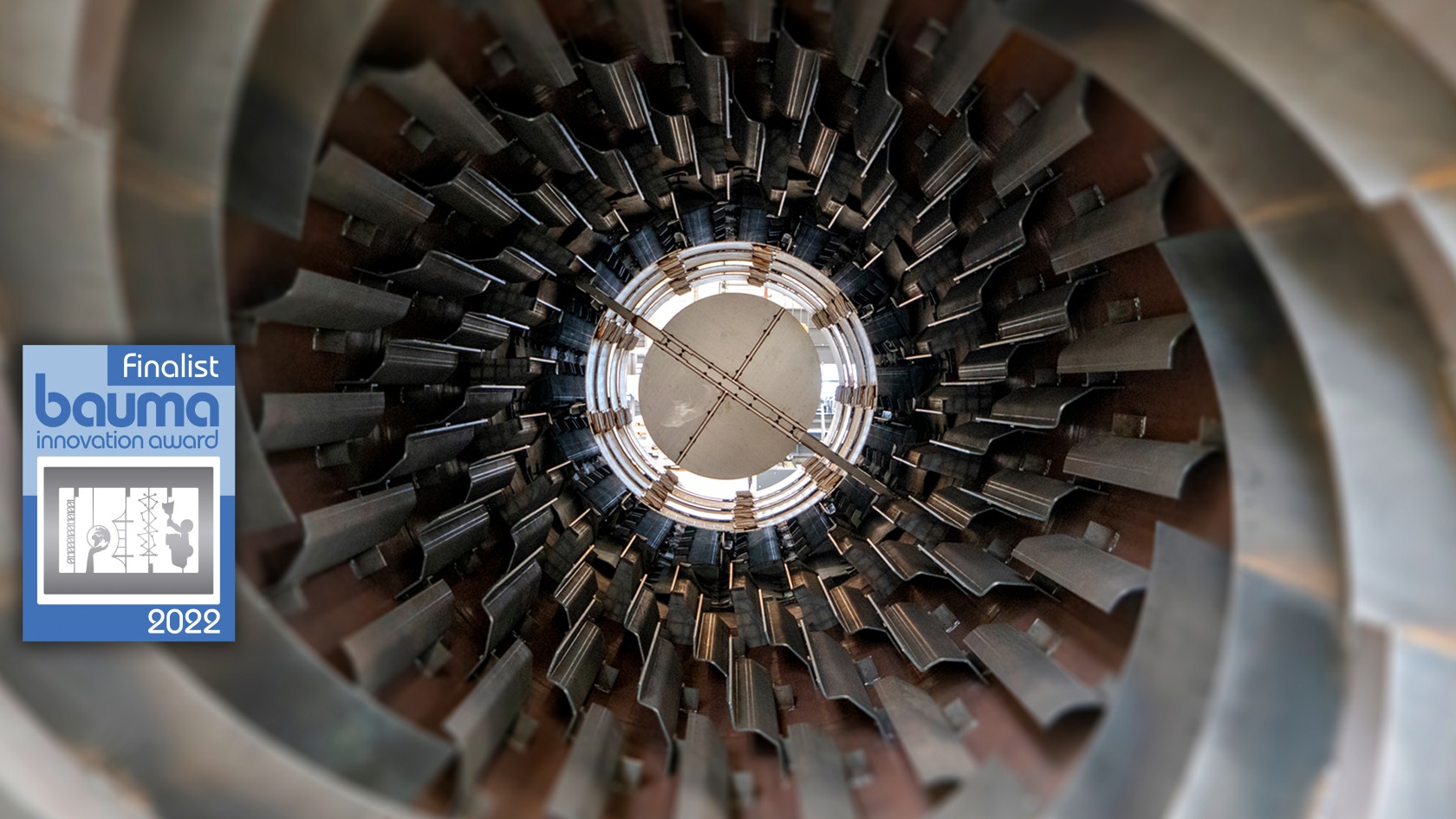

Benninghoven | World premiere: REVOC system

Environmentally friendly technology also contributes to securing the future of mixing plants sites

The Benninghoven REVOC system is a pioneering technology that enables plant owners to implement higher recycling ratios while complying with stringent emissions limits. The patented technology supplements existing hot and cold recycling systems in asphalt mixing plants, reducing the total carbon emissions (Ctot) with up to 50 % recycling material added. Specified limits are not exceeded. In Germany, for example, the levels remain below the limit required by the TA-Luft regulation.

The challenge: complying with more stringent emissions limits

Emissions limits are being tightened up in many regions worldwide. Complying with these is a challenge in asphalt production. At the same time, using the highest possible amount of recycling material is becoming ever more important in terms of saving resources.

While reclaimed asphalt can be added to the production process with reliable cold and hot recycling technologies, this does create higher emissions of total carbon (Ctot, volatile organic compounds (VOC)). When reclaimed asphalt is heated, part of the Ctot concentrations evaporate from the bitumen contained in the recycling material. These have a higher greenhouse potential than CO₂ and are hazardous to health in higher concentrations.

These emissions have to be reduced as much as possible with the objective of securing both the future of the plant site and the operating license for existing asphalt mixing plants. Owners of existing plants can achieve both with the REVOC innovation – which Benninghoven will be presenting at the BAUMA 2022 exhibition for the first time.

Solution: REVOC reduces Ctot emissions by up to 50 %

The REVOC system is a solution for reducing emissions from asphalt production by making the existing mixing plants more efficient and more environmentally friendly. The option of adding up to 60 % recycling material can reduce emissions to comply with legal limits. At the same time, the higher recycling content also increases the economic efficiency of existing plants.

Firstly, the REVOC system extracts the emissions directly where they are generated, primarily from the mixer in the asphalt mixing plant, where heated mineral, recycling material and bitumen come together to be mixed into fresh asphalt. The generated vapours have increased Ctot concentrations and are therefore moved to the REVOC system for thermal processing. This step uses the energy already generated for drying and heating the virgin mineral and is therefore extremely energy-efficient. Most importantly, however, the technology can reduce Ctot emissions by up to 50 %.

New Benninghoven patent: the REVOC system. The efficient technology combines the drying and heating of virgin mineral with a reduction in emissions, using the already generated energy.

REVOC system supports plant owners in many ways

The Benninghoven innovation meets the increasing demands from customers and the more stringent requirements from authorities in many countries. This also includes the “Technical Instructions on Air Quality Control” (TA-Luft) regulation that applies in Germany. The more stringent limits of < 50 mg/m3 in this regulation can be met reliably with the REVOC system.

“We already have several REVOC systems in operation. This provides our development engineers with valid data, allowing us to offer our customers and their mixing foremen with precise support for optimum operation of the REVOC system and the entire plant,” says Katharina Kratz, Research & Development Development Engineer.

With the increased plant performance, high recycling content and reduced emissions, plant owners are perfectly prepared for the future. In particular in light of the ever more stringent specifications from authorities, REVOC is the innovative solution for environmentally friendly operation of asphalt mixing plants.

The REVOC system reduces a large part of the total carbon emissions.

Benninghoven leads the way for sustainable asphalt production

In addition to the hot-gas generator technology and fuels from renewable sources, the REVOC system is another essential component with which Benninghoven drives sustainability and efficiency in the asphalt production industry.

The REVOC system from BENNINGHOVEN has reached the finals of the Bauma Innovation Award 2022 in the category ‘Climate Protection’.

Public Relations

Reinhard-Wirtgen-Straße 2

53578 Windhagen

Germany