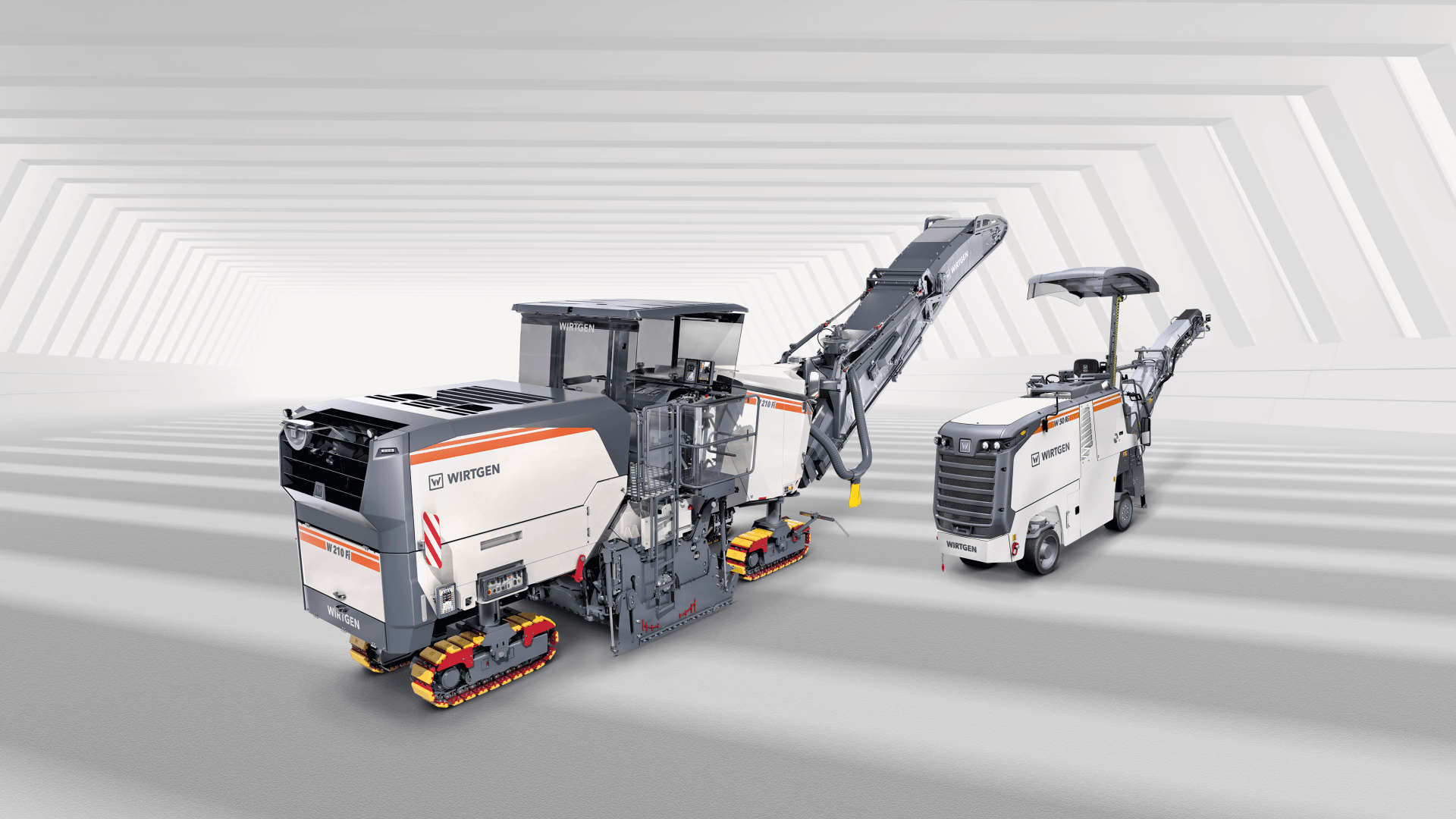

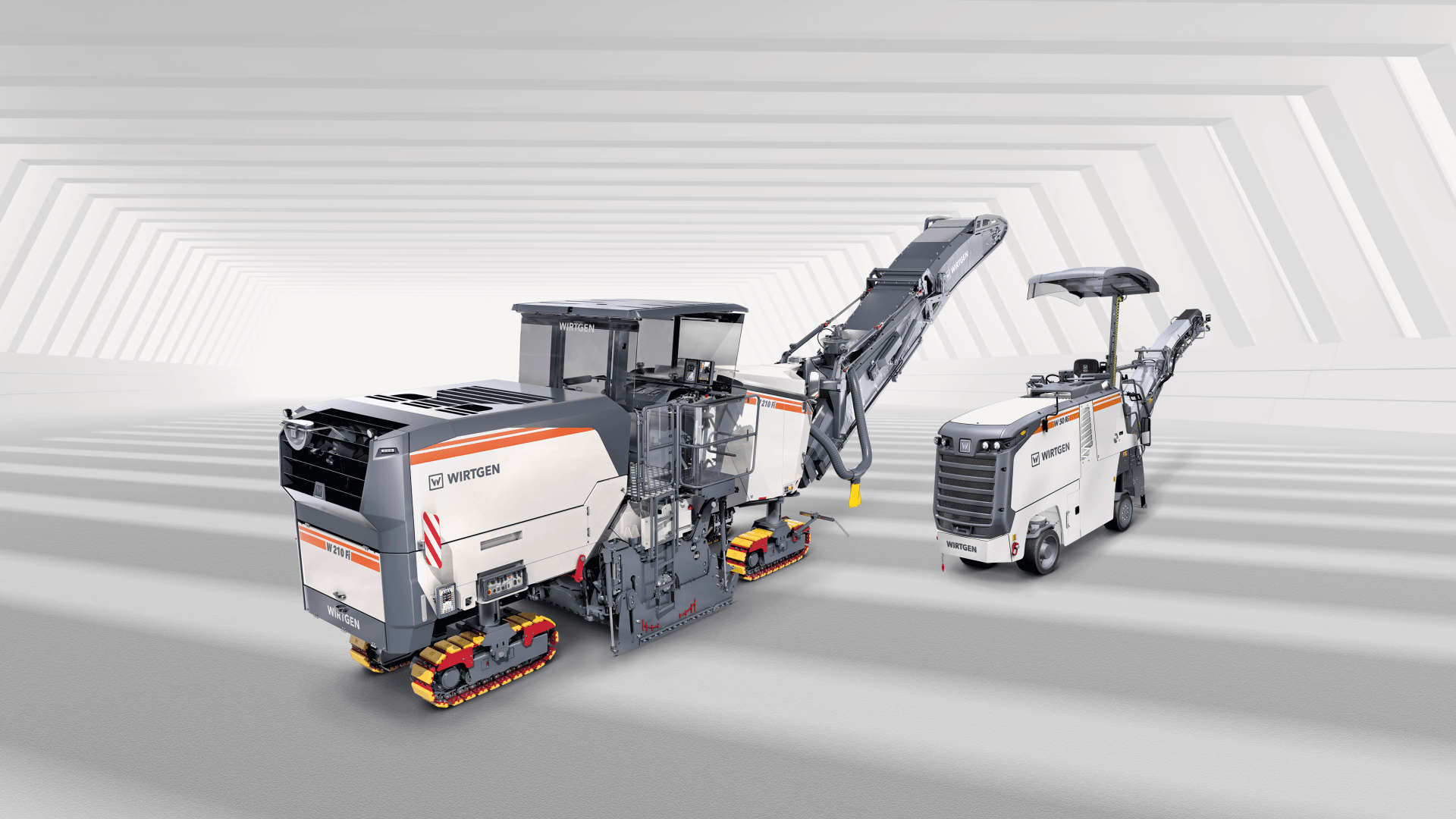

Cold milling machines

Asphalt and concrete pavements can be cost-effectively removed with cold milling machines. The range of applications extends from the complete removal of asphalt and concrete to the layer-by-layer removal and levelling of asphalt and concrete surfaces. With WIRTGEN cold milling machines, it is possible to machine working widths from 35 cm up to 4.40 m and working depths up to 35 cm in a single pass. In addition, a large number of different milling drums, such as ECO cutters or fine milling drums, ensure that machines can be used with a high degree of flexibility.

Small milling machines have a wheeled chassis and a milling drum positioned at the rear. The granulated RAP broken up by the rotating milling drum is transferred to a height-adjustable discharge conveyor that can be slewed to either side for direct loading onto waiting transport vehicles. The compact rear loaders are highly manoeuvrable and feature a right rear wheel that can be swivelled inwards for milling flush to the edges of obstacles. A wide range of milling drums enables the small milling machines to tackle a broad spectrum of applications ranging from partial pavement rehabilitation and milling tie-ins to the rehabilitation of floors in industrial buildings.

All details, illustrations and texts are non-binding and may include special equipment. We reserve the right to make technical changes without prior notice. Performance data are dependent upon actual operational conditions.